South Korea, renowned for its technological advancements, faces significant environmental challenges, particularly in the disposal of car batteries. The country generates thousands of tons of battery waste annually, necessitating efficient and environmentally friendly disposal methods. A facility capable of processing 1000kg of car batteries per hour aligns perfectly with Korea’s stringent recycling policies and sustainability goals. This article explores the intricacies of car battery disposal in Korea, emphasizing the regulatory framework and technological approaches.

The Necessity for Efficient Car Battery Disposal

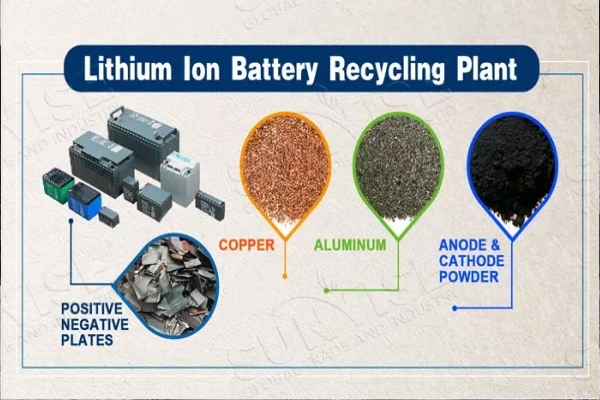

Car batteries, particularly lead-acid and lithium-ion types, contain hazardous materials like lead, sulfuric acid, and lithium, which pose severe environmental and health risks if not properly managed. Efficient disposal and recycling processes are essential to mitigate these risks and recover valuable materials for reuse.

South Korea’s Recycling Policies

Disposal and Recycling Technologies

Environmental and Economic Benefits

Contact Us