In the field of lithium-ion batteries recycling, anode sheets are a key component that can be recycled to recover valuable materials such as copper, aluminum, and graphite. Moreover, the increasing demand for electric vehicles and portable electronic devices is fueling the growth of the lithium-ion battery market. As a result, the volume of waste anode sheets is also expected to increase, creating a pressing need for effective recycling solutions. As of 2025, some of the most popular anode sheet recycling equipment are as follows:

Top 3 anode sheet recycling equipment in 2025

Mechanical Shredding and Screening Equipment: Mechanical shredding and screening equipment is used to break down anode sheets into smaller particles and then screen them according to different particle sizes. This helps to separate different components in the anode sheets and prepare them for further processing and recycling. It is a basic and important equipment in the anode sheet recycling process.

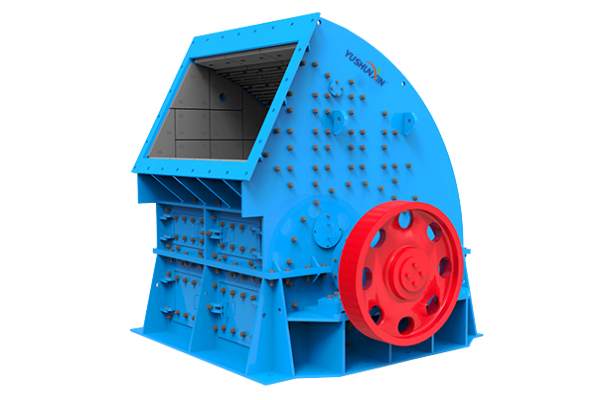

Hammer Vibration Crushing and Airflow Sorting Equipment: This kind of equipment is widely used in the recycling of anode sheets. It first uses hammer vibration crushing to effectively achieve the mutual disassembly and separation of anode materials from the collector. Then, through the airflow sorting process based on the size and shape differences of particles, it can achieve the effective separation and recovery of valuable materials in the anode sheets. For example, it can separate aluminum and other materials from the anode sheets, which is very important for recycling and reusing these materials.

Thermal Treatment Equipment: Some anode sheets may require thermal treatment to remove organic matter or other impurities. Thermal treatment equipment (pyrolysis furnace) can heat the anode sheets to a certain temperature under specific conditions to achieve the purpose of purification and separation. This kind of equipment is suitable for the recycling of anode sheets with complex compositions or high impurity contents.

Complete process of positive electrode sheet recycling

Contact Us