Many harmful substances are produced during the recycling process of circuit boards. While noting the economic benefits in PCB recycling, are you aware of the risks posed by toxic components in waste to workers and environment? If they are not effectively treated, they will cause great harm. Next, let us understand what equipment our circuit board recycling production line is equipped with to solve this problem!

Risks of Toxic Components in Waste

The safety of equipment during operation, especially protective measures when handling hazardous substances, is a major concern for customers. So, how can we ensure that hazardous substances generated in circuit board recycling production lines are controlled?

Effective Dust Control and Purification Strategies for PCB Recycling

Actually, in the physical treatment of waste PCBs, materials are mainly recovered through mechanical crushing, grinding, and sorting. This method generates fewer harmful gases compared to chemical and thermal treatments (such as incineration), but it may still release some dust and gases. Below are potential issues and corresponding solutions:

Potential Harmful Dust and Gases

Corresponding Dust and Purification Equipment

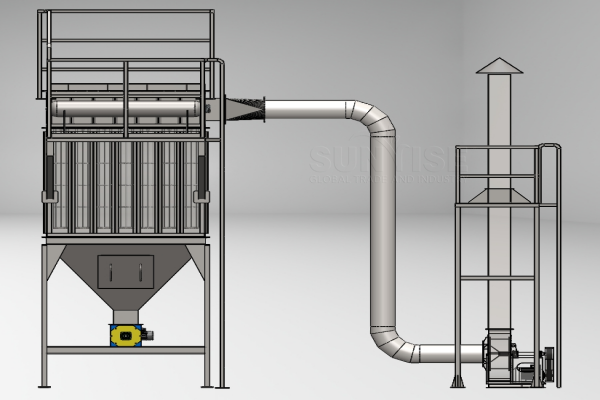

Bag filter:

Bag filter uses fabric to filter dusty gas, so that dust is deposited on the surface of the fabric to purify the gas. It can effectively filter out most of the solid particles and is a widely used high-efficiency dust collector. It is very suitable for capturing dust generated during mechanical processing.

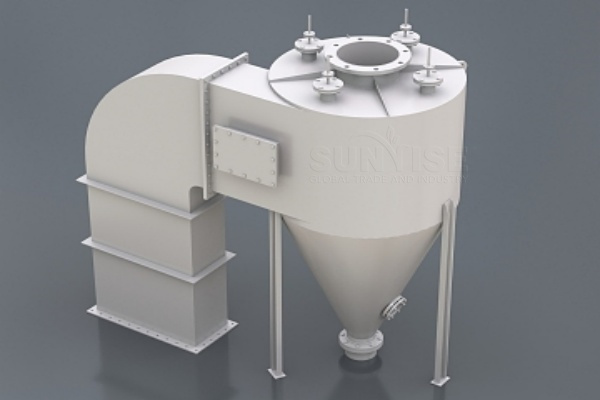

Cyclone dust removal:

Pre-treat high-concentration dust-containing gas to reduce dust concentration. The cyclone dust collector uses centrifugal force to separate dust particles and is an effective primary dust removal equipment. When the dust-laden airflow enters the cyclone dust collector in a tangential direction, due to the rotational motion, the larger dust particles are thrown toward the wall of the dust collector under the action of centrifugal force, and then fall along the wall due to gravity and enter the collector, while the clean gas is discharged from the top.

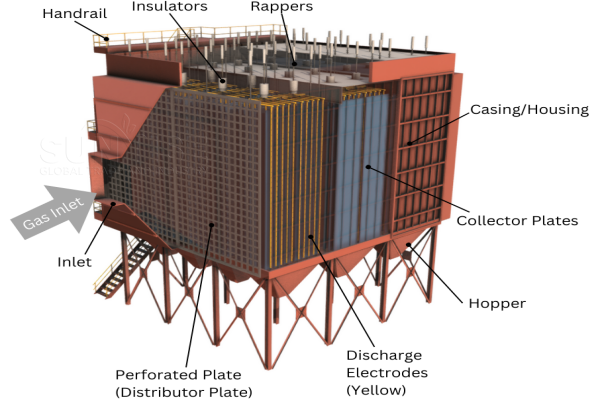

Electrostatic dust removal:

The electrostatic precipitator (ESP) ionizes the gas through corona discharge, and the dust particles are charged under the action of the electric field force, and move to the dust collecting electrode and deposit under the action of the electric field force, thereby separating from the airflow. It is particularly suitable for capturing finer dust and aerosol particles.

Although it is relatively safe to use physical means to treat waste circuit boards, it is still necessary to equip appropriate dust removal and air purification equipment to ensure the health of workers and the safety of the production environment. According to the specific operation and material characteristics, choosing the right dust removal equipment can effectively reduce the hazards of dust and gas, and the equipment should also be regularly maintained and inspected to ensure its normal operation.

Contact Us