During the tire pyrolysis process, we obtain a valuable byproduct called tire pyrolysis oil (TPO). TPO is a recycled renewable raw material and fuel for various industries. It has great potential and brings huge profits to related practitioners. By the end of 2031, the global tire-derived fuel market is expected to reach a value of 510.91 million US dollars. Next, let us take you to do an analysis of TPO. It may be a reference for you to establish a waste tire recycling production line.

What is Recycled Tire Pyrolysis Oil?

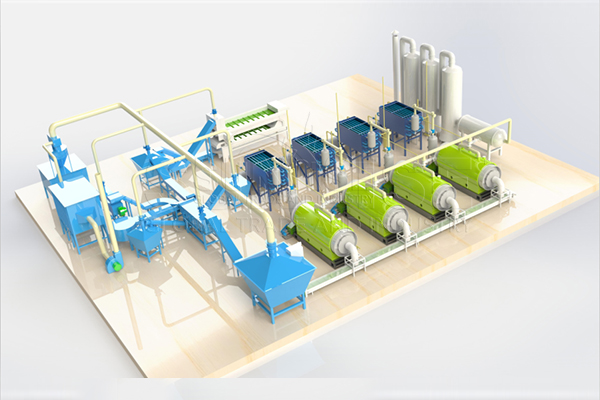

Pyrolysis technology generates TPO through the recycling of end-of-life tires (ELT). At SUNRISE, the results of the pyrolysis process are: recovered tire oil, recovered Carbon Black, recovered steel, and recovered gas.

End-of-life tires (ELT) pose a challenge due to their durable and robust tire materials. Pyrolysis offers a solution to recycle ELT by using a thermochemical process. In this process, we heat tire crumbs resulting from tire shredding to 550°C in an environment devoid of oxygen. The intricate polymers in the used tires decompose. This happens through a combination of thermal and chemical reactions. The decomposition yields oils, carbon black, and gas.

SUNRISE is one of the few factories in China that delivers electronic waste recycling equipment to the world. Our headquarter(YOTO Group) was established in 2013. Experienced SUNRISE has strict control over the pyrolysis process and strives to recycle 100% of ELT.

Applications of Tire Pyrolysis Oil

Can tire pyrolysis oil be a viable substitute for conventional petroleum products? The answer is affirmative if the properties and composition of the recycled TPO closely resemble those of traditional oil. Tire pyrolysis oil finds utility as a fuel for engines, heating systems, and power generation. It also serves as a raw material for the manufacturing of carbon black and various chemicals.

Industrial Equipment Fuel

Following desulfurization, we can blend recycled TPO with diesel fuel. This makes it function as a substitute for fossil fuels in motor vehicles, diesel burners, generators, and construction machinery. We derive TPO from recycled scrap tires. It contributes to the EU’s goal of achieving climate neutrality by 2050. Many people have chosen to use TPO produced by pyrolysis to replace first-generation biofuels.

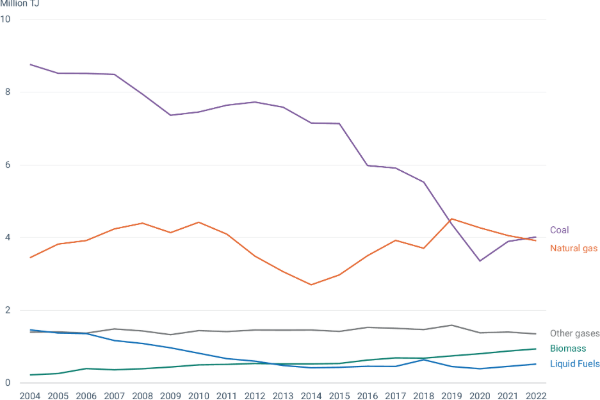

Fuel consumption in the EU-27, per fuel type

Tire pyrolysis oil heating

Because recycled TPO’s properties are similar to those of diesel, we can use the same pipelines in industrial environments to directly replace diesel with it as a heat source. TPO has applications in industrial settings, including its use for heating in processes like boiler heating.

Utilizing Tire Pyrolysis Oil for Power Generation

Furthermore, the gross calorific value of TPO is impressive. This makes it a cost – effective alternative to coal or natural gas in power generation.

TPO possesses comparable energy levels to conventional fossil fuel oil, exceeding coal by 25-50% and wood by 100-200%.

Many nations rely on imported fossil fuels for electricity and heating needs. While all countries have vehicles and generate end-of-life tires (ELT), the recycling rates in numerous countries remain low. By converting ELT into TPO, these nations can decrease their dependence on imported fossil fuels.

Tire pyrolysis oil for high-value chemical production

After we distill the tire pyrolysis oil in the distillation machine, we can separate it into different components, and these components can be used to produce a variety of high – value chemicals.

Light hydrocarbons: We can separate the light part of the pyrolysis oil into light hydrocarbons such as ethylene and propylene during the distillation process. These compounds are important raw materials for the production of plastics, synthetic rubber and other chemical products.

Aromatic hydrocarbons: We can use the aromatic hydrocarbons (like benzene, toluene, xylene, etc.) in the distilled pyrolysis oil to produce chemicals such as phenol and caprolactam. People widely use these chemicals in the pharmaceutical, fragrance and dye industries.

Carbon Black Production: We can use the remaining heavy fractions to produce carbon black. Carbon black is widely used in industries such as rubber products, plastics, inks and coatings. Currently, for the majority of virgin carbon black (vCB) production, we rely on fossil fuel feedstocks. Approximately 90% to 95% of it comes from this source.

Solvent Production: We can use some of the fractions as industrial solvents. These solvents play an important role in the manufacture of products such as paints, coatings and cleaning agents.

What are the advantages of utilizing recycled tire pyrolysis oil?

Recycled tire pyrolysis oil (TPO) offers significant economic and environmental benefits. Particularly, it can serve as a sustainable alternative to traditional fossil fuels in various industries.

Superiority of TPO over other fuels

Reduction of mining emissions and carbon footprint

Potential for decentralized, small-scale TPO production

How can SUNRISE assist with integrating TPO into your applications?

As industries move towards circular practices, the utilization of recycled TPO presents promising opportunities across various sectors.We know that tire recycling is a cause that benefits people. Therefore, SUNRISE commits to providing efficient waste tire recycling production line for enterprises or individuals who want to recycle waste tires into oil, and increase the application of tire oil by providing reliable and high-quality tire oil extraction equipment. Contact us to know more about SUNRISE waste recycling machines and TPO.

Contact Us