Why do you choose lithium-ion vehicle batteries to recycle?

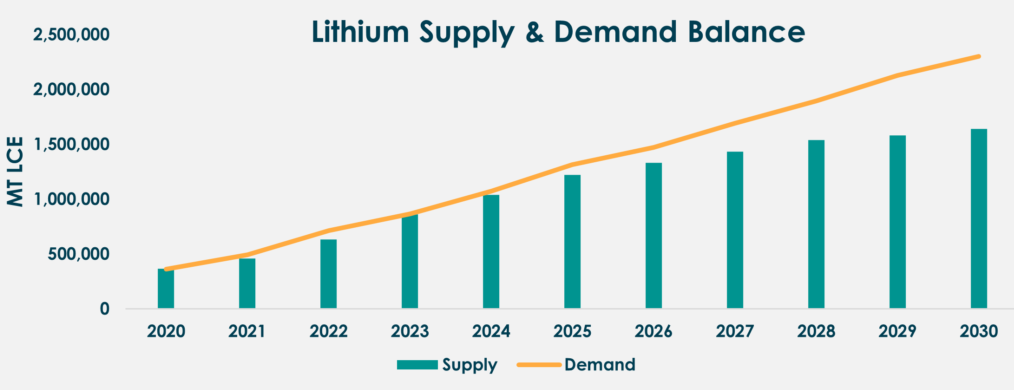

Firstly, these batteries are rich in valuable raw materials. Lithium, cobalt, nickel, and manganese are among the crucial elements they contain. With the soaring demand for new lithium-ion batteries in the expanding electric vehicle market, recycling them provides a sustainable source of these scarce and costly materials, reducing the heavy reliance on mining and its associated environmental impacts.

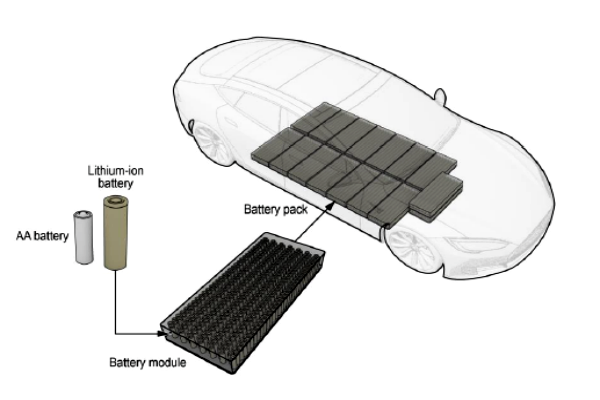

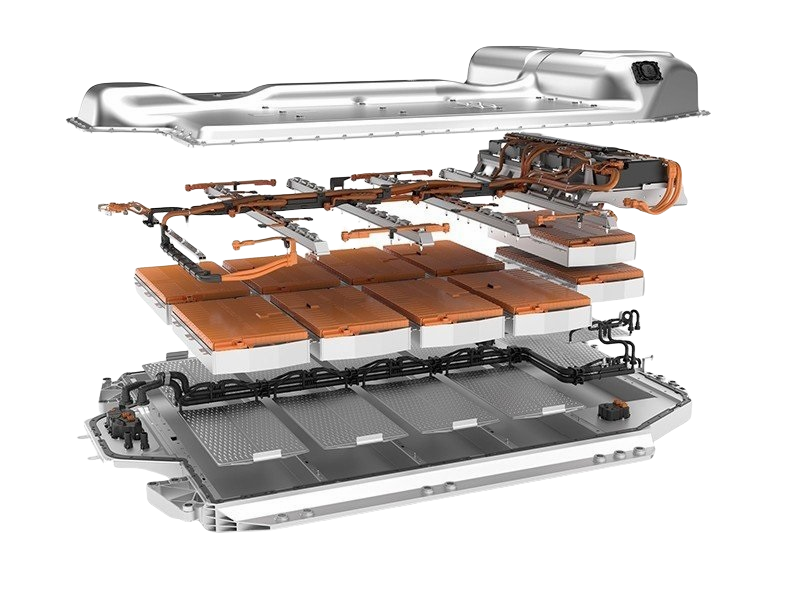

Secondly, lithium-ion vehicle batteries are designed for relatively easy disassembly. Lithium-ion batteries come in various cell, module, and pack sizes. Multiple cells making up a module and multiple modules making a battery pack. A battery pack for an electric vehicle may need hundreds or thousands of cells. This modular design not only speeds up the recycling operations but also minimizes the risk of damage to the recoverable materials, ensuring higher yields of quality materials for reuse.

Last but not least, the wide range of utilisable materials within lithium-ion vehicle batteries offers multiple revenue streams. Beyond the precious metals for new battery production, other components like the casing materials and electrolytes can be recycled or repurposed in various industries, making the whole recycling process economically viable and environmentally beneficial.

In summary, recycling lithium-ion vehicle batteries is a win-win choice for resource conservation and economic benefits.

Why do you use mechanical separation to recover lithium from spent lithium-ion vehicle batteries?

In the pursuit of efficient and sustainable lithium recovery from spent lithium-ion vehicle batteries, mechanical separation has become the preferred choice over chemical methods. Here’s why, considering the aspects of pollution, difficulty of production line operation, and price.

From the pollution perspective, mechanical separation holds a distinct advantage. Unlike some chemical-based recovery methods that involve the use of copious amounts of hazardous reagents, mechanical processes rely mainly on physical forces such as size screening, magnetic attraction, and gravity sorting. This means minimal generation of toxic chemical waste that could contaminate soil, water, and air. For instance, there’s no need for strong acids or alkalis that would otherwise pose serious disposal challenges and environmental risks, ensuring a cleaner and more eco-friendly recycling operation.

When it comes to the operation difficulty of the lithium batteries recycling production line, mechanical separation offers simplicity and ease of management. The equipment involved, like crushers, sieves, and magnetic separators, operates based on straightforward physical principles. Workers can be trained relatively quickly to understand and oversee the processes, reducing the likelihood of operational errors. The machinery is also designed for continuous and stable operation, with fewer complex chemical reaction parameters to monitor and adjust compared to alternative methods. This streamlines the production flow and boosts overall productivity.

In terms of price, mechanical separation proves to be a cost-effective solution. The initial investment in mechanical separation equipment is generally more affordable than that required for elaborate chemical extraction setups. Additionally, the operational costs are lower as it consumes less energy and requires minimal chemical inputs, which are often expensive. The maintenance of mechanical devices is also relatively straightforward and inexpensive, with fewer components prone to corrosion or complex breakdowns caused by chemical reactions. Overall, it provides an economical pathway to lithium recovery, enhancing the viability and profitability of the recycling business.

Our customers from all over the world gave the above feedback above. That’s why SUNRISE is offering customers an e-waste recycling proposal with physical shredding and separation.

Contact Us