Electronic waste (e-waste) contains metal components such as gold, silver, copper, aluminum and iron, as well as other materials such as silicon, plastic and glass. Recycling and extracting these materials can bring considerable profits. As a major producer of electronic waste, India attaches great importance to such projects.

Proposal for Indian customer

On June 21, 2024, Indian customer Patel wanted us to design a recycling production line that can process 500 kg of electronic waste per hour. He specifically asked us to design an advanced system that only retains the necessary machines on the production line and eliminates all auxiliary equipment.

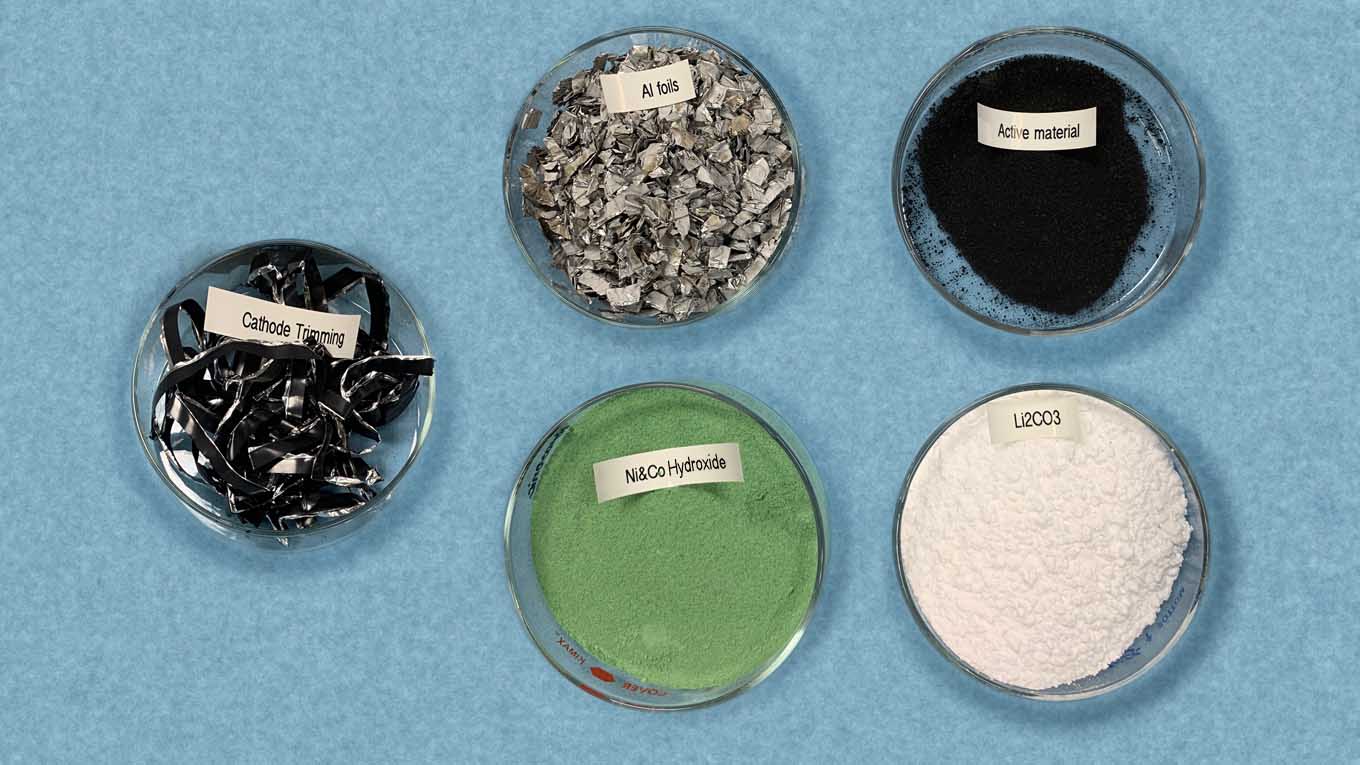

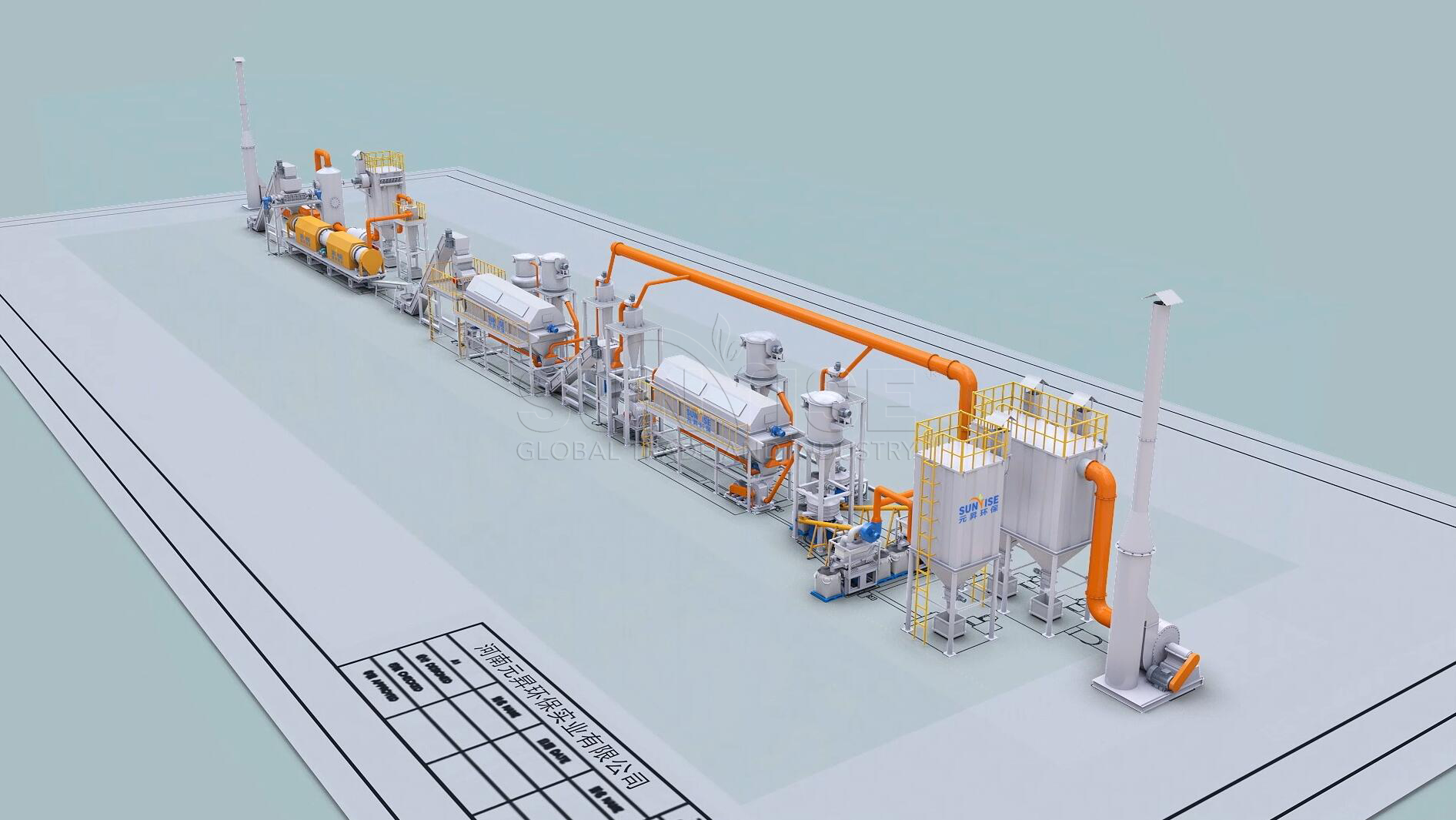

In response to customer needs, we provide three different solutions for the recycling of circuit boards, photovoltaic panels and lithium batteries. These solutions have their own characteristics, and customers need to choose according to the actual situation of their own raw material sources to find the most suitable solution.

For example, the waste circuit board recycling production line is the result of our extensive research and development by our engineers, combining the latest advances in domestic and foreign technologies. The entire production line adopts advanced physical recycling technology, which can mechanically crush and recycle various types of waste printed circuit boards. The production line includes shredder, crusher, dismantling machine and high-voltage electrostatic separator, as well as dust removal equipment. This line ensures a high metal recovery rate, with a purity of more than 99% of the recovered metal. At the same time, we hope to help you reap the maximum profit at the lowest cost. The total equipment cost is estimated to be between $20,000 and $30,000. We are proud of our innovative solutions.

The Indian customer maintained open communication with us and expressed satisfaction with our technology and services. We took them to visit our factory and answered their questions one by one during the meeting. We enjoy discussing with every customer, and we are glad to have won their trust through our efforts.

Why do we recommend you to do e-waste recycling in India?

Why choose SUNRISE as your e-waste recycling plant supplier?

In the case mentioned in this article, we have successfully delivered the most advanced waste circuit board recycling machine solution with an hourly processing capacity of 500 kg to our valued customers in India, marking an important step towards efficient and sustainable e-waste recycling. Actually SUNRISE’s machine stands out for several reasons

Advanced Technology

Our production line integrates the latest physical recycling technologies, ensuring high efficiency and effectiveness in the recycling process. Our machinery is designed to maximize the purity of recovered metals, achieving over 99%.

Cost-Effectiveness

We aim to provide solutions that deliver maximum profit at the lowest operational costs, optimizing your returns on investment.

Customization and Flexibility

We understand that each project has unique requirements. Our team works closely with clients to tailor the production line to their specific needs and reduce unnecessary expenses.

Comprehensive Support

Throughout the process, we maintain open communication with our clients, providing extensive on-site support, factory visits, and detailed meetings to address all questions and concerns.

Proven Track Record

Our successful implementation of e-waste recycling production line in India is a testament to our expertise and reliability. Our customers have expressed high satisfaction with our technology and services, further solidifying our reputation as a leading supplier in the industry.

Choosing SUNRISE as your equipment supplier means partnering with a company that prioritizes innovation, efficiency, and customer success. We are proud of our role in advancing sustainable e-waste recycling practices globally. looking forward to cooperate with you!

Contact Us