We want to provide our customers with cutting edge e-waste recycling solutions. Let us explore the benefits, applications, and technical aspects of dual shaft shredders for e-waste recycling and provide you with expert advice to make an informed investment decision.

Key Benefits and Applications of Double Shaft Shredder Machines

Double shaft shredders are engineered to provide efficient and reliable shredding of various materials. They are vital in industries ranging from recycling to manufacturing, offering significant advantages that address both operational and environmental needs.

Superior Shredding Efficiency and Versatility

Double shaft shredder machines are known for their exceptional shredding efficiency and versatility, which make them suitable for a wide array of applications.

High Torque and Low Speed: Double shaft shredders operate with high torque and low speed, ensuring efficient shredding of even the toughest materials. This design minimizes energy consumption while maximizing shredding power, resulting in lower operational costs.

Material Versatility: These machines can handle a diverse range of materials, including plastics, rubber, wood, metal, and electronic waste. This versatility makes them an ideal choice for recycling facilities, manufacturing plants, and waste management centers.

Uniform Output: The dual shafts work in sync to produce a consistent and uniform output size, which is crucial for further processing or recycling. This uniformity enhances the quality of the end product and improves the efficiency of subsequent processes.

Reduced Downtime: The robust construction and high-quality components of our double shaft shredders ensure minimal downtime and maintenance requirements. This reliability translates to uninterrupted operations and higher productivity.

Enhancing Operational Efficiency and Environmental Responsibility

Investing in a double shaft shredder machine not only improves your operational efficiency but also supports your environmental sustainability goals.

Optimized Resource Utilization: By efficiently shredding waste materials, double shaft shredders enable the recycling and repurposing of resources that would otherwise be discarded. This optimization contributes to a circular economy and reduces the need for virgin materials.

Waste Volume Reduction: The shredding process significantly reduces the volume of waste, making it easier to handle, transport, and store. This reduction in volume also decreases the frequency of waste disposal, leading to cost savings in waste management.

Energy Recovery: In certain applications, shredded materials can be used as a source of energy. For instance, shredded wood and biomass can be utilized in bioenergy production, while shredded plastics can be processed into fuel. This energy recovery further enhances the environmental benefits of using a double shaft shredder.

Compliance with Regulations: Proper waste management and recycling practices are increasingly mandated by regulations. Utilizing a double shaft shredder helps you comply with local and international environmental standards, avoiding potential legal issues and penalties.

Technical Specifications and Performance Data

To help you understand the capabilities of our double shaft shredder machines, we provide detailed technical specifications and performance data. These insights will guide you in selecting the right model for your specific needs.

Shredding Capacity: Our double shaft shredders come in various models with shredding capacities ranging from 500 kg/h to 5000 kg/h. This wide range ensures that there is a suitable model for every scale of operation, from small recycling facilities to large industrial plants.

Motor Power: The motor power of our machines varies between 15 kW and 150 kW, providing the necessary torque and power to handle different types of materials. This flexibility allows you to choose a machine that matches your specific shredding requirements.

Cutter Design: Our shredders feature robust and durable cutters made from high-quality steel. The cutter configuration is designed to optimize shredding efficiency and minimize wear and tear. Additionally, the cutters are easily replaceable, ensuring minimal downtime during maintenance.

Control System: Advanced control systems are integrated into our double shaft shredders to enhance operational efficiency and safety. These systems include automated monitoring, load sensing, and emergency stop functions, ensuring reliable and safe operation.

Noise and Vibration Levels: Despite their powerful operation, our double shaft shredders are designed to operate with minimal noise and vibration. This feature is particularly important in environments where noise reduction is critical.

Professional Investment Advice and Recommendations

Assessing Your Shredding Requirements

- 1

Material Type: Identify the types of materials you need to shred. Different materials have varying hardness, density, and composition, which will influence the choice of cutter design and motor power.

- 2

Volume and Throughput: Estimate the volume of material you need to process on a daily or weekly basis. This estimation will help you determine the appropriate shredding capacity required to meet your operational demands.

- 3

Output Size: Define the desired output size of the shredded material. Some applications may require fine shredding, while others may need coarser output. Choosing a machine with adjustable output size settings can provide greater flexibility.

Evaluating Total Cost of Ownership

- 1

Energy Efficiency: Opt for machines with high energy efficiency to reduce operational costs. Energy-efficient machines consume less power, resulting in significant cost savings over time.

- 2

Maintenance and Support: Reliable after-sales support and maintenance services are crucial for ensuring the longevity and performance of your shredder. At SUNRISE, we offer comprehensive maintenance packages and technical support to keep your machine running smoothly.

- 3

Durability and Longevity: Investing in a high-quality, durable machine may have a higher upfront cost, but it will pay off in the long run by minimizing downtime and reducing the frequency of replacements.

Ensuring Compliance and Sustainability

- 1

As environmental regulations become more stringent, ensuring compliance is critical to avoid legal issues and penalties. Additionally, adopting sustainable practices enhances your corporate image and aligns with global sustainability goals.

- 2

Regulatory Compliance: Stay informed about local and international regulations related to waste management and recycling. Choose a shredder that meets or exceeds these standards to ensure full compliance.

- 3

Sustainability Goals: Integrate the use of double shaft shredders into your broader sustainability strategy. Promote the environmental benefits of efficient waste management and recycling to stakeholders and customers.

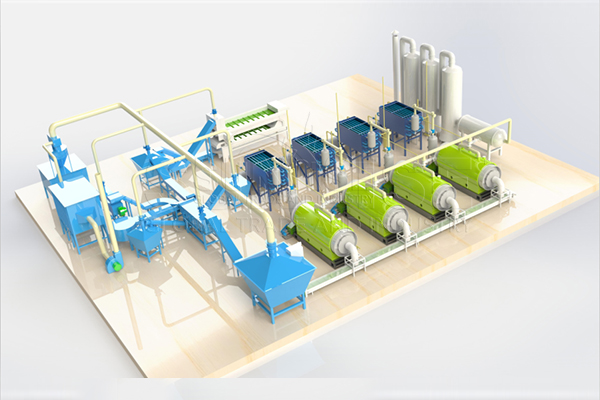

As a professional e-waste recycling production line supplier, we know exactly the importance of double shaft shredder. We have been working hard for integrating the use of dual shaft shredder into your e-waste recycling strategy. Therefore, whether you are interested in the dual-shaft shredder or e-waste recycling project, feel free to contact us!

Contact Us