Industrialization has led to the invention of many electrical and electronic devices that have made our lives relatively easy. This has led to an increase in the generation of electronic waste (e-waste). In 2019, the global generation of e-waste was about 53.6 million tons, and it is expected to reach 74 million tons by 2030. In 2019, Asia, America, and Europe generated 50 million tons of e-waste, while Africa and Oceania generated 2.9 million tons and 0.7 million tons, respectively. So, what is considered e-waste? If you have interest, please continue reading.

First, check this video. Then you can get a preliminary understanding of the current situation of e-waste……

Definition of e-waste

Electronic waste, commonly known as e-waste, has received increasing attention in recent years for its far-reaching social, environmental and economic impacts. With the rapid development of electronic devices and consumers constantly upgrading their electronic products, the amount of e-waste generated has surged.

E-waste announced by the European Commission includes discarded electronic and electrical equipment. This type of waste includes a variety of technological products that have exceeded their service life or are inefficient. Electronic devices contain harmful elements and, unlike ordinary garbage generated in cities, they pose a major threat to ecosystems and human health.

Many countries, especially developing countries, lack the infrastructure to properly handle and recycle e-waste, leading to environmental and health risks caused by improper e-waste disposal. Currently, many people use dangerous methods such as open burning, landfilling, open dumping, informal dismantling and manual recycling. These practices pose a significant risk to public health. In order to avoid the high cost of proper disposal, many developed countries choose to export e-waste to developing countries such as India and Africa. These countries are currently struggling with the problem of insufficient infrastructure for e-waste management.

What are the recyclable e-wastes?

Lithium batteries

Because lithium batteries contain a lot of reusable materials:

Lithium: Lithium is a key component of lithium batteries, and recycled lithium can be used to make new lithium batteries. For example, in electric vehicles and portable electronic devices, the recycling and reuse of lithium is essential to reduce raw material costs and ensure the supply of lithium resources.

Cobalt: Many lithium batteries contain cobalt in the positive electrode materials, such as lithium cobalt oxide (LiCoO₂). Cobalt is a rare and expensive metal, and recycled cobalt can be reused in the battery manufacturing industry, reducing dependence on newly mined cobalt resources.

Nickel: Some lithium batteries (such as nickel-cobalt-manganese oxide (NCM) batteries) contain nickel. The recycling of nickel helps to recycle resources, and in the production of new batteries, recycled nickel can meet some of the raw material needs.

Copper and aluminum: Copper and aluminum are usually used in the casing and electrode connection parts of lithium batteries. These metals can be purified through recycling processes and then reused in electronic equipment manufacturing or other industrial uses.

Recycling methods:

Lithium batteries recycling production line Includes steps such as disassembly, crushing and screening. First, disassemble the waste lithium battery, separate the shell, electrode and other parts, then crush the electrode material, and separate copper, aluminum and other metals by screening and magnetic separation.

Circuit board

Recycled materials:

Precious metals: Circuit boards contain precious metals such as gold, silver, and platinum. Gold is mainly used for pins, contacts and connection parts of some high-precision electronic components on circuit boards because it has good conductivity and corrosion resistance. Silver is often used in circuit boards and some components such as capacitors. These precious metals have high recycling value and can be reused in industries such as electronic component manufacturing or jewelry.

Non-ferrous metals: Copper is the most important non-ferrous metal in circuit boards and is used to make circuits and connecting wires of various electronic components. Recycled copper can be used to make new wires, cables and electronic components. In addition, circuit boards also contain a small amount of tin, which is mainly used for welding electronic components. The recycled tin can be used again in the production of welding materials.

Rare metals: Such as tantalum, which is used in some high-performance capacitors on circuit boards. The recycling of tantalum helps meet part of the demand for rare metals in the electronics industry because tantalum resources are relatively scarce.

Circuit board recycling method:

First, disassemble the circuit board to remove large components, and then break the circuit board into small particles. Then use physical sorting methods such as gravity sorting, magnetic separation and electrostatic sorting to separate different metals and non-metallic materials.

Solar panels

Recyclable materials:

Silicon: Silicon is the main material of photovoltaic panels, especially in crystalline silicon photovoltaic panels. Recycled silicon can be reused in photovoltaic panel manufacturing after purification and other processes, or used in other semiconductor-related industries.

Silver: The electrode part of photovoltaic panels usually contains silver, which is used to collect and conduct current. Recycled silver can be used to make new photovoltaic panel electrodes or conductive parts of other electronic devices.

Aluminum: The frame of photovoltaic panels is usually made of aluminum, and recycled aluminum can be used to make new photovoltaic panel frames or other aluminum products.

Glass: The panel of photovoltaic panels is mainly made of glass. Recycled glass can be used in industries such as architectural glass and automotive glass after cleaning and processing.

How to recycle waste solar panel:

First, use a frame remover to disassemble the photovoltaic panel and separate components such as glass, aluminum frame and battery cells. After the glass is removed, the photovoltaic panel is crushed with a crusher. The silicon wafers separated from the battery cells are first crushed and ground into smaller particles or powders, and then screened using screening equipment to filter out silicon, copper, and EVA glue.

Policies for electronic waste recycling

Let’s take some countries as examples!

| Country | Policy | Outcome | |

| 1. | United States | State level E-waste Laws | Approach towards minimized inconsistent recycling and illegal dumping |

| 2. | Germany | Extended Producer responsibility (EPR) | High rates of recycling, with reduced illegal dumping |

| 3. | Sweden | Producer responsibility with fees | Effective collection and recycling system |

| 4. | China | National E-waste Recycling program | Efforts to formalize the recycling sector, and reduction of environmental pollution |

| 5. | India | E-waste Management rules 2016 | Towards implementation and development of compliance |

Summary

The mountains of discarded electronics are not only an eyesore, but also a potential concern for our health and our planet. At the same time, electronic waste recycling has great potential because it is able to extract valuable metals, which are present in higher concentrations in electronic waste than in their natural sources. In addition, the technology of different electronic waste recycling methods optimizes the efficiency and cost-effectiveness of these methods. These methods involve electronic products such as circuit boards, photovoltaic panels, lithium batteries, etc.

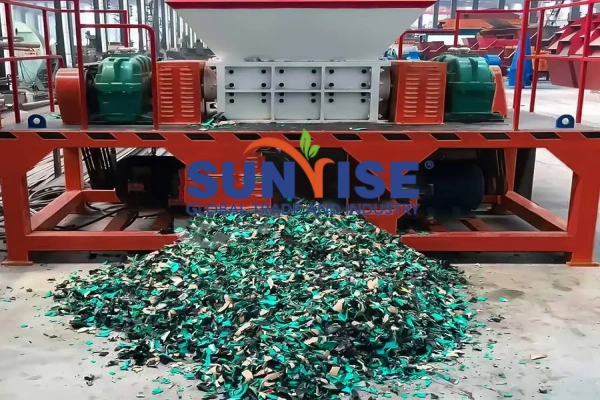

There is still a lot of work need to do to develop sustainable and efficient electronic waste management solutions. As a professional e-waste recycling machine manufacturer, SUNRISE is also working hard to cope with the growing problem of e-waste management. SUNRISE’s e-waste recycling production lines are helping lots of clients to save resources and generate economic benefits. At the same time, we will adjust the proposal according to the situation of the customer’s country to ensure that every customer can get the most efficient electronic waste recycling production line.

So, please do not hesitate to contact us, we’ll give you advice from a professional perspective.

Contact Us