More and more tyre recyclers are processing waste tyres into saleable materials and selling them. There are already professional waste tyre recycling lines on the market. Waste tyre recycling systems vary in design depending on capacity. This affects area occupancy, cost, labour, etc. Before purchasing a tire recycling line, we’d love to help you confirm your output. How about a processing capacity of 200 kg/h? On 7 October 2023, a customer from Singapore inquired us.

Here are the details of our communication on this case.

YUSHUNXIN: If you want to process 200kg of waste tires per hour, we can recommend you to choose our waste tire refining production line. It is an option for operating a small tire recycling production line.

There are two reasons: First, small waste tire refining production lines usually have a lower initial investment cost, while being able to recover the oil in the tires at a higher oil yield. Faodaidh e coinneachadh ri feumalachdan cinneasachaidh gun a bhith a 'toirt cus uidheamachd no sgudal ghoireasan a bharrachd.

Air an làimh eile, Mar as trice bidh uidheamachd beaga air a dhealbhadh airson a bhith nas motha cruinn agus sìmplidh, Barrachd sùbailte gus obrachadh, agus mar as trice tha Cosgaisean cumail suas nas ìsle, a tha freagarrach airson àite cuibhrichte no companaidhean tòiseachaidh.

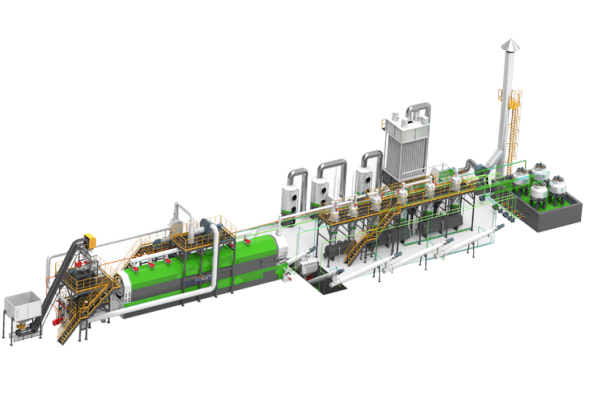

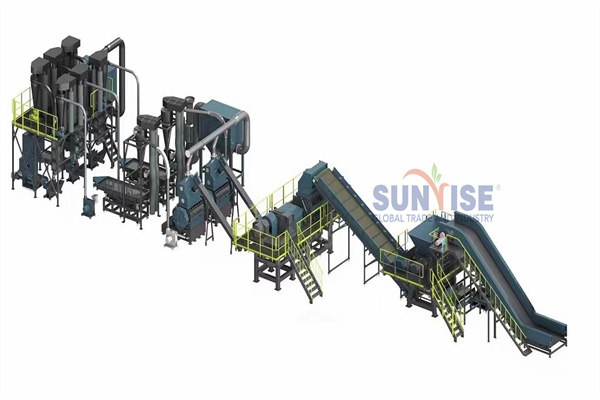

How To Design 200kg/h Tire Pyrolysis Production Line

Mar as trice bidh iad a 'toirt a-steach bonn Inneal shredding, a reactair pyrolysis, a Càirdean uachdar Airson a bhith a 'fuarachadh agus a' toirt a-mach na gasaichean pyrolysis gus toraidhean leaghaidh fhaighinn (leithid ola pyrolysis), a Purtification gas agus siostam cruinneachaidh, agus a siostam làimhseachaidh faochadh Airson an fhuigheall cruaidh (leithid gualain dubh) fhàgail às deidh pyrolysis. Cuir fios thugainn uair sam bith, Cuiridh sinn gnàthachadh am fuasgladh pyrolysis dhut.

Dè a th 'ann an Design De loidhne cinneasachaidh pyrolysis 200kg / h

Mar as trice bidh iad a 'toirt a-steach bonn Inneal shredding, a reactair pyrolysis, a Càirdean uachdar Airson a bhith a 'fuarachadh agus a' toirt a-mach na gasaichean pyrolysis gus toraidhean leaghaidh fhaighinn (leithid ola pyrolysis), a Purtification gas agus siostam cruinneachaidh, agus a siostam làimhseachaidh faochadh Airson an fhuigheall cruaidh (leithid gualain dubh) fhàgail às deidh pyrolysis. Cuir fios thugainn uair sam bith, Cuiridh sinn gnàthachadh am fuasgladh pyrolysis dhut.

The Area Requirement of 200kg/h Tire Pyrolysis Production Line System

The Area Requirement of 200kg/h Tire Pyrolysis Production Line System

An dèidh fios a bhith agad mun dealbhadh, the customer in Singapore noticed the space requirements of the tire pyrolysis recycling line. He wanted to know if the workshop could accommodate a 200kg/h tire pyrolysis production line?

Generally speaking, a 200kg/h tire pyrolysis production line includes equipment, operating space, material storage and transportation channels, etc., and usually requires a workshop area of more than 500m2. Here is a detailed layout plan:

How Much Does A 200kg/h Tire Pyrolysis Production Line Cost

San fharsaingeachd, cosgais a 200 kg/h Tire Pyrolysis Ath-chuairteachadh Ath-chuairteachadh Loidhne Riochdachadh faodaidh iad atharrachadh a rèir diofar nithean leithid càileachd phàirtean, Feartan a bharrachd, agus Brand.

Ach, Faodaidh tu a bhith an dùil tasgadh mun cuairt $14,000 gu $21,000. Bhiodh an dearbh chosgais air a dhearbhadh às deidh dhaibh a bhith a 'beachdachadh air riatanasan sònraichte an loidhne riochdachaidh, leithid an seòrsa reactair, siostam teasachaidh, agus siostam fuarachaidh air a chleachdadh.

Tha e cudromach toirt fa-near gu bheil iad sin dìreach tuairmsean garbh Agus dh 'fheumadh a' chosgais fhèin a bhith air a thomhas stèidhichte air Measadh mionaideach air an uidheamachd, Stàladh, agus cosgaisean co-cheangailte ri co-cheangailte ri còmhdhail, Làbarach stàlaidh, agus às deidh – Seirbheis reic.

How Much Does A 200kg/h Tire Pyrolysis Production Line Cost

San fharsaingeachd, cosgais a 200 kg/h Faodaidh loidhne riochdachaidh taidheir pyrolysis atharrachadh a rèir diofar nithean leithid càileachd phàirtean, Feartan a bharrachd, agus Brand. Ach, Faodaidh tu a bhith an dùil tasgadh mun cuairt $14,000 gu $21,000. Bhiodh an dearbh chosgais air a dhearbhadh às deidh dhaibh a bhith a 'beachdachadh air riatanasan sònraichte an loidhne riochdachaidh, leithid an seòrsa reactair, siostam teasachaidh, agus siostam fuarachaidh air a chleachdadh.

Tha e cudromach toirt fa-near gu bheil iad sin dìreach tuairmsean garbh Agus dh 'fheumadh a' chosgais fhèin a bhith air a thomhas stèidhichte air Measadh mionaideach air an uidheamachd, Stàladh, agus cosgaisean co-cheangailte ri co-cheangailte ri còmhdhail, Làbarach stàlaidh, agus às deidh – Seirbheis reic.

Ach, Faodaidh tu cuideachd innse dhuinn dè a tha thu airson ath-chuairteachadh bho na taidhrichean? Ola pyrolysis or carbon black? You can determine the solution in this way.

If your objective is to obtain pyrolysis oil from a tire pyrolysis facility operating at 200 kg/h

| Equipment Name | Extractable Product | Unit Price (Approximate) |

|---|---|---|

| Tire Shredding Machine | Prepares shredded tires for pyrolysis | $2,000 – $20,000 |

| Pyrolysis Reactor | Initiates the pyrolysis process to produce pyrolysis gas | $40,000 – $200,000 |

| Condenser | Condenses pyrolysis gas into liquid oil | $5,000 – $20,000 |

| Oil – Gas Separator | Separates the condensed oil from uncondensed gas | $10,000 – $30,000 |

| Oil Storage Tank | Stores the extracted pyrolysis oil | $3,000 – $8,000 |

| **Total** | – | $145,000 |

If you want to recover carbon black from a 200 kg/h tire pyrolysis line

| Equipment Name | Extractable Product | Unit Price (Approximate) |

|---|---|---|

| Tire Shredding Machine | Prepares shredded tires for pyrolysis | $2,000 – $20,000 |

| Pyrolysis Reactor | Initiates the pyrolysis process to produce carbon black and other by-products | $40,000 – $200,000 |

| Carbon Black Separator | Separates carbon black from other solid residues | $10,000 – $20,000 |

| Carbon Black Storage Tank | Stores the extracted carbon black | $2,000 – $5,000 |

| **Total** | – | $128,000 |

If your objective is to obtain pyrolysis oil from a tire pyrolysis facility operating at 200 kg/hIf your objective is to obtain pyrolysis oil from a tire pyrolysis facility operating at 200 kg/h

| Equipment Name | Extractable Product | Unit Price (Approximate) |

|---|---|---|

| Tire Shredding Machine | Prepares shredded tires for pyrolysis | $2,000 – $20,000 |

| Pyrolysis Reactor | Initiates the pyrolysis process to produce pyrolysis gas | $40,000 – $200,000 |

| Condenser | Condenses pyrolysis gas into liquid oil | $5,000 – $20,000 |

| Oil – Gas Separator | Separates the condensed oil from uncondensed gas | $10,000 – $30,000 |

| Oil Storage Tank | Stores the extracted pyrolysis oil | $3,000 – $8,000 |

| **Total** | – | $145,000 |

If you want to recover carbon black from a 200 kg/h tire pyrolysis lineIf you want to recover carbon black from a 200 kg/h tire pyrolysis line

| Equipment Name | Extractable Product | Unit Price (Approximate) |

|---|---|---|

| Tire Shredding Machine | Prepares shredded tires for pyrolysis | $2,000 – $20,000 |

| Pyrolysis Reactor | Initiates the pyrolysis process to produce carbon black and other by-products | $40,000 – $200,000 |

| Carbon Black Separator | Separates carbon black from other solid residues | $10,000 – $20,000 |

| Carbon Black Storage Tank | Stores the extracted carbon black | $2,000 – $5,000 |

| **Total** | – | $128,000 |

The above is the specific content of our communication with the Singapore customer. In addition to the proposal of waste tire pyrolysis production line, we can also provide you with business plans for circuit board recycling, solar panel recycling and lithium battery recycling line. If you need it, please contact us at any time.

Contact Us