YSX High – Quality Activated Carbon Adsorbers plays a crucial role in purification, absorption and recycling. You will find it when designing lithium battery recycling proposals, photovoltaic panel recycling solutions, circuit board recycling solutions, and even tire recycling solutions. It’s a cornerstone of environmental protection efforts across e-waste recycling industries.

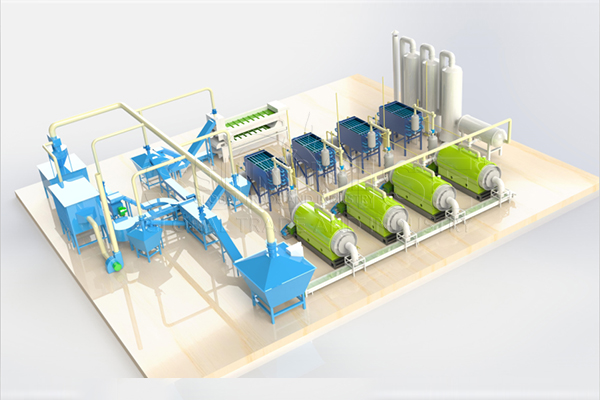

Activated Carbon Adsorber Appearance

उदाहरण के लिए, this adsorption machinery is ingeniously crafted with a simple yet effective structure. Comprising three main components – the box body, activated carbon filter cotton, and high – quality activated carbon, it ensures optimal performance. The box body, with dimensions of 2.5m1.5m1.3m, provides a sturdy housing. Its six – drawer design allows for easy replacement and maintenance of the activated carbon and filter cotton. This not only simplifies the upkeep process but also ensures that the machinery can operate continuously with minimal downtime.

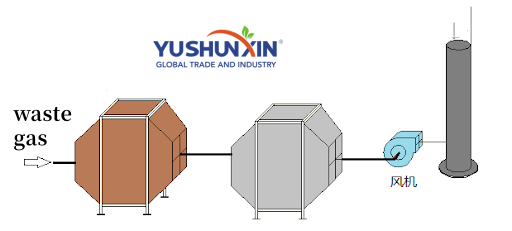

How Does Box Adsorber Work?

When organic waste gas comes in through the air duct, the magic starts. Activated carbon, which has lots of tiny holes and a big surface, acts like a strong magnet for pollutants. It catches the harmful stuff in the waste gas through physical and chemical attraction. The activated – carbon filter cotton helps even more by trapping small particles. In the end, the gas that comes out is clean and meets or is better than the strictest emission rules, so it’s safe to let out into the air.

Applications For Active Carbon Adsorption Machinery

In the complex and rapidly evolving field of e – waste recycling, which encompasses the recycling of lithium – ion batteries, circuit boards, photovoltaic panels, and tires, active carbon adsorption machinery plays a significant role.

Function within the Lithium – ion Battery Recycling

During the recycling process of lithium – ion batteries, various chemical substances are released. उदाहरण के लिए, harmful gases such as hydrogen fluoride (HF) may be generated due to the decomposition of electrolyte components. Active carbon adsorption machinery can effectively capture these harmful gases. The large – surface – area pores of the active carbon provide numerous adsorption sites, allowing HF molecules to be adsorbed onto the surface of the active carbon. This not only helps in purifying the exhaust gas from the recycling process but also prevents environmental pollution and protects the health of recycling workers.

Application in Circuit Board Recycling

Circuit board recycling involves processes like metal extraction and component separation. Organic solvents are often used in the recycling of circuit boards, and these solvents can volatilize into the air, forming volatile organic compounds (VOCs). Active carbon adsorption machinery can adsorb these VOCs. It acts as a filter, trapping the organic molecules in the air stream. By doing so, it reduces the emission of harmful substances into the atmosphere, ensuring that the recycling facility complies with environmental regulations regarding air quality.

Role Played in Solar Panel Recycling

When recycling photovoltaic panels, some toxic substances such as lead and cadmium may be released during the pv panels disassembly and processing steps. Although these substances are in solid or particulate form, there may also be trace amounts of volatile compounds associated with them. Active carbon adsorption machinery can adsorb these volatile contaminants, preventing them from being released into the environment. Additionally, it can help in the purification of any gases generated during the thermal treatment processes involved in photovoltaic panel recycling.

Use in Tire Recycling

Tire recycling usually involves processes like shredding और पाइरोलिसिस. During pyrolysis, a variety of gases are produced, including sulfur – containing compounds, benzene, and other aromatic hydrocarbons. These gases are not only harmful to the environment but also have a pungent odor. Active carbon adsorption machinery can efficiently adsorb these sulfur – containing and aromatic compounds. It improves the air quality around the tire – recycling plant, making the working environment more pleasant and reducing the impact on the surrounding community.

Why Choose YSX Active Carbon Adsorption Machinery?

Active carbon adsorption machinery is an indispensable part of the e – waste recycling process in multiple sub – fields. Its ability to adsorb harmful substances and purify the air not only contributes to environmental protection but also ensures the sustainable development of the e – waste recycling industry.

हमसे संपर्क करें