As a trusted supplier in the renewable energy sector, we understand that building a solar panel processing plant can be a significant investment. However, with careful planning and strategic choices, you can establish a high-quality facility at a low cost. In this article, we will guide you through the key steps to achieve this, focusing on site selection, equipment procurement, and operational efficiency. Our goal is to help you make informed decisions that will optimize your budget and ensure long-term success.

Site Selection and Infrastructure

- 1

Affordable Land and Utility Costs:

We recommend looking for locations where land prices and utility costs are relatively low. Industrial zones or areas with government incentives for renewable energy projects can be particularly cost-effective. Additionally, ensure that the site has easy access to necessary utilities such as electricity, water, and transportation networks. This will reduce initial infrastructure costs and facilitate smooth operations.

- 2

Government Incentives and Grants:

Many governments offer incentives, grants, and tax breaks for renewable energy projects. Research the available programs in your chosen location and apply for any that you qualify for. These financial incentives can significantly offset your initial investment and reduce the overall cost of building your plant.

- 3

Existing Structures:

Consider repurposing existing industrial buildings or warehouses for your solar panel processing plant. This can save you a substantial amount on construction costs. Ensure that the structure meets the necessary requirements for a clean and controlled manufacturing environment. Minor modifications or retrofitting can make an existing building suitable for solar panel production at a fraction of the cost of new construction.

Equipment Procurement and Installation

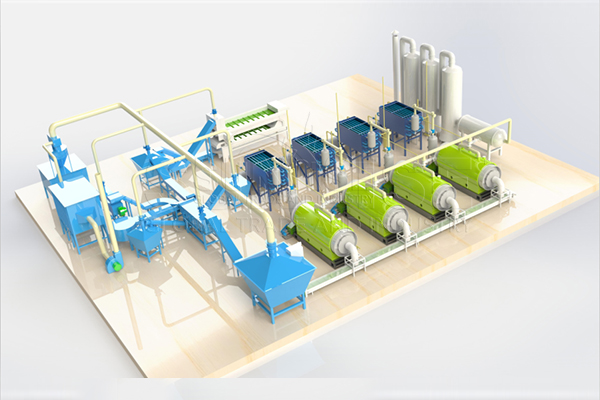

Modular and Scalable Solutions

Opt for modular and scalable equipment that can grow with your production needs. This allows you to start with a smaller investment and expand your capacity as demand increases. Modular systems are often more cost-effective and easier to install, reducing both initial costs and long-term operational expenses.

Supplier Partnerships

Establish strong partnerships with suppliers who can offer favorable terms and ongoing support. Bulk purchasing agreements and long-term contracts can lead to significant cost savings. Additionally, many suppliers provide maintenance and training services, which can enhance the efficiency and lifespan of your equipment.

Operational Efficiency and Cost Management

Contact Us