Do You Know Why Algeria Needs Tire Recycling?

The Current State of Used Tires in Algeria

Algeria faces a growing challenge with used tire disposal. Globally, over 10 billion tires are discarded annually, and as a major automotive market in North Africa, Algeria contributes significantly to this figure. While exact local data is limited, neighboring countries like Egypt and Morocco report annual tire waste increases of 6–8%, a trend likely mirrored in Algeria. This makes waste tire recycling more important there.

Currently, most Algerian used tires end up in landfills or are illegally burned, releasing toxic chemicals like dioxins and heavy metals into the air and soil. For instance, open burning emits 20 times more CO₂ than legal thermal recycling methods, worsening air quality and public health risks.

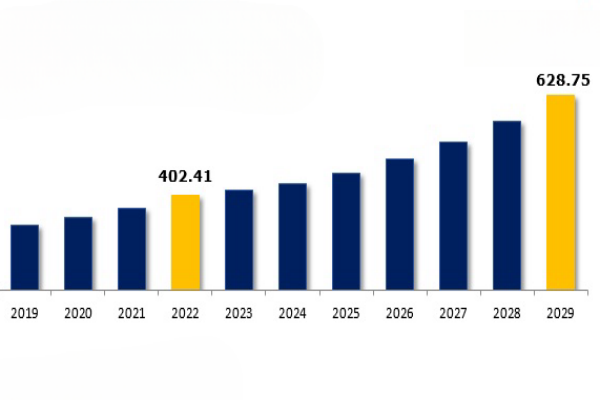

Algerian Economic Opportunities and Policy

Three steps to tire recycling in Algeria

Stage 1: Tire Pre-Treatment

Equipment: Tire shredders and materials separators.

Key Metrics: A mid-sized shredder processes 2–5 tons/hour, requiring 50–100 kW of electricity.

Process: Tires are cut into chips, and steel wires are magnetically extracted for resale.

Stage 2: Pyrolysis Treatment

Tire pyrolysis machine is important for your tire recycling business, so you need to choose the most suitable one. You can choose between continuous and batch reactors type.

- 1

Tire pyrolysis machine is important for your tire recycling business, so you need to choose the most suitable one. You can choose between continuous and batch reactors type.

- 2

Batch pyrolysis reactors (lower upfront cost, 50,000–200,000) are ideal for small plants but require manual loading.

- 3

Emission Standards: Ensure equipment meets EU-2010/75/EU guidelines to avoid harmful gas release.

Stage 3: Product Refinement

Pyrolysis oil is distilled into fuel, while carbon black is milled for industrial use.

Tire Recycling Equipment Purchasing Guide

Tire Recycling Business Risk Management Strategies

By adopting these strategies, Algeria can transform tire waste into economic assets while mitigating environmental harm. As a used tyre recycling business investor, you should prioritize certified suppliers, leverage local policies, and build resilient supply chains to thrive in this emerging sector.

Contact Us