We received an inquiry from a South African client who is eager to establish a waste tire recycling production line in South Africa. The raw materials he has at hand mainly come from passenger cars, trucks, light commercial vehicles, and industrial tires. Thanks to the abundant supply of waste tires in his region, he hopes the processing capacity of the production line can exceed 1 ton.

Two popular Tyre Recycling Solutions in 2025

Physical Recycling Tires Solution

The first step in the physical recycling tire process is shredding. You’ll use the double-shaft shredder. A recommended model for 1 ton processing capacity is the YSX double-shaft shredder, which features a powerful motor with a power output of around 55 – 75 kW. It is designed to handle various sizes and types of tires, efficiently tearing them into smaller pieces.

The shredded material then passes through a series of screening equipment. For instance, a vibrating screen with a screen size of about 3 – 5 mm mesh is used to separate out the finer particles from the coarser ones. This sieving process helps to ensure the uniformity of the material for further processing. After screening, the rubber granules can be further processed and refined according to different market demands, such as being used in the production of rubber mats, playground surfaces, or modified asphalt.

Pyrolysis Tires Plan

In the pyrolysis process, the waste tires are first loaded into a pyrolysis furnace. A suitable pyrolysis furnace for this application, operates at a temperature range of 400 – 600 °C.

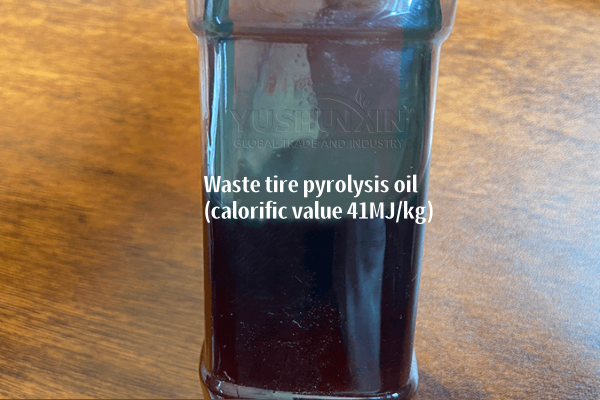

Inside the furnace, under the effect of high temperature and in the absence of oxygen, the tires break down chemically. The gaseous products are then directed to a condensation system. The condensation equipment, with a heat exchange area of approximately 20 – 30 square meters, cools down the gases to separate out the condensable components, mainly oils.

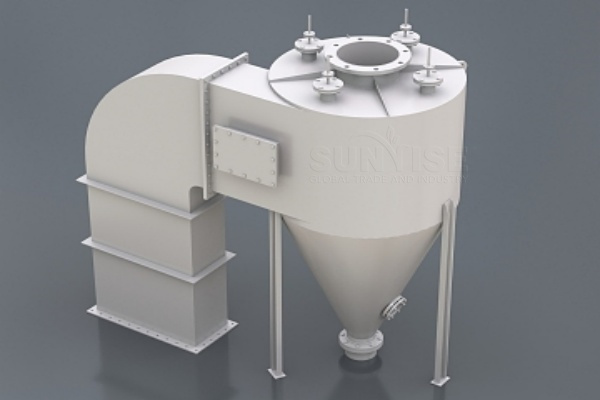

Meanwhile, a dust removal device, such as a bag house filter with a filtration efficiency of over 99%, is installed to capture and remove the fine particulate matter generated during the pyrolysis process, ensuring that the exhaust gas meets environmental standards.

The solid residue left in the pyrolysis furnace, mainly carbon black, can be further processed and sold to industries such as the rubber and ink manufacturing sectors. The pyrolysis oil obtained can be used as a fuel substitute in some industrial boilers or further refined for other applications.

How to Build a Waste Tire Recycling Plant?

Is Tire Recycling Business Profitable in South Africa?

Our foreign trade services are designed to make your purchasing experience as convenient as possible. We offer flexible payment options to suit your financial situation, whether it’s through letters of credit, wire transfers, or other secure payment methods. Our after-sales service team is always on standby to provide technical support and maintenance guidance. If you need detailed information about installation cases in South Africa, please don’t hesitate to contact us. We will be happy to provide you with valuable references to help you make an informed decision.

Contact Us