As the adoption of electric vehicles (EVs) accelerates globally, the need for efficient and sustainable recycling solutions for electric car batteries becomes increasingly critical. Therefore, let’s explore an issue of great concern to our customers, which is the cost of recycling electric car batteries.

Key Factors Influencing the Cost of Recycling Electric Car Batteries

Initial Investment in Recycling Infrastructure

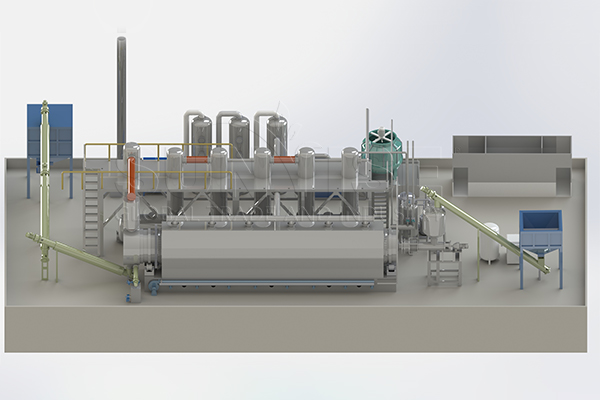

Facility and Equipment

Establishing a state-of-the-art recycling facility involves advanced machinery such as shredders, separators, and chemical processing units. For instance, a high-capacity shredder capable of processing 1 ton of batteries per hour can cost around $200,000 to $500,000. Advanced separation units may range from $150,000 to $300,000, depending on their technology and capacity.

Compliance and Safety Measures

Ensuring that your facility meets local and international safety standards is crucial. This includes investments in safety equipment, training, and certifications, which can add $50,000 to $100,000 to your initial costs.

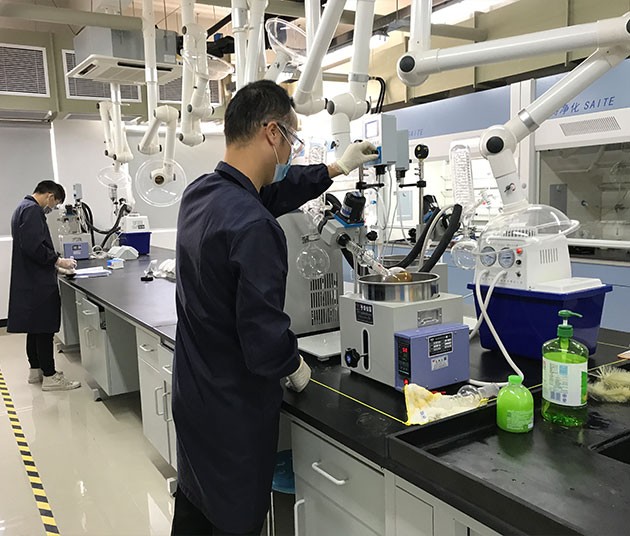

Research and Development

Investing in R&D is essential. Allocating around 5-10% of your total investment to R&D can lead to process optimizations and cost reductions over time. For example, an annual R&D budget of $100,000 can yield significant long-term savings.

Operational Costs and Labor Considerations

Energy Consumption

Recycling processes are energy-intensive. For instance, a typical recycling plant processing 10 tons of batteries per day might consume 1,000 kWh per day, costing around $100 per day at $0.10 per kWh. Over a year, this adds up to $36,500.

Labor Costs

Skilled labor is essential. Salaries for skilled technicians can range from $50,000 to $70,000 annually. Assuming a workforce of 10 technicians, annual labor costs could be around $500,000 to $700,000.

Material Handling and Transportation

These costs can vary. Transporting batteries within a 100-mile radius can cost $200 to $400 per trip, depending on volume and regulatory requirements. Annually, this might add up to $50,000 to $100,000.

Revenue Streams and Economic Viability

Recovery of Valuable Materials

Electric car batteries contain valuable materials such as lithium, cobalt, nickel, and manganese. For example, lithium can be sold at around $10,000 per ton. If your facility processes 3,000 tons of batteries annually, recovering 200 tons of lithium could yield $2 million.

Second-Life Applications

Repurposing used batteries for energy storage can generate additional revenue. For instance, second-life batteries can be sold at $100 per kWh. A facility repurposing 1,000 kWh of batteries annually could generate $100,000.

Government Incentives and Grants

Leveraging incentives can significantly reduce costs. For example, a government grant covering 20% of initial investment might save $200,000 if your facility's setup cost is $1,000,000.

Impact of Production Scale on Recycling Costs

Small-Scale Recycling Operations

Lower Initial Investment: Small-scale facilities typically require $500,000 to $1,000,000 in capital investment, making it easier to enter the market.

Flexibility and Adaptability: These facilities can quickly implement new technologies without significant disruptions.

Limited Revenue Potential: With a processing capacity of 1 ton per day, annual revenue from lithium recovery might be around $200,000, assuming a recovery rate of 20%.

Medium-Scale Recycling Operations

Medium-scale operations balance investment costs and processing capacity, ideal for regions with moderate battery disposal volumes.

Moderate Initial Investment: Medium-scale facilities require $1,000,000 to $2,000,000 in capital investment.

Economies of Scale: Processing 5 tons per day, the cost per ton decreases, enhancing profitability. Annual revenue from lithium recovery could be around $1,000,000.

Enhanced Revenue Potential: With higher processing volumes, partnerships with battery manufacturers and energy storage companies can boost revenue.

Large-Scale Recycling Operations

Large-scale operations, with substantial initial investments, offer high processing capacities and revenue potential.

High Initial Investment: Large-scale facilities require $3,000,000 to $5,000,000 in capital investment.

Maximized Economies of Scale: Processing 10 tons per day, the cost per ton is significantly reduced. Annual revenue from lithium recovery might reach $2,000,000.

Diverse Revenue Streams: Extensive processing capacity allows exploring various revenue streams, including material recovery and second-life applications.

Professional Recommendations for Optimizing Recycling EV Batteries Costs

At YUSHUNXIN, we provide expert advice to help you optimize your recycling operations and reduce costs:

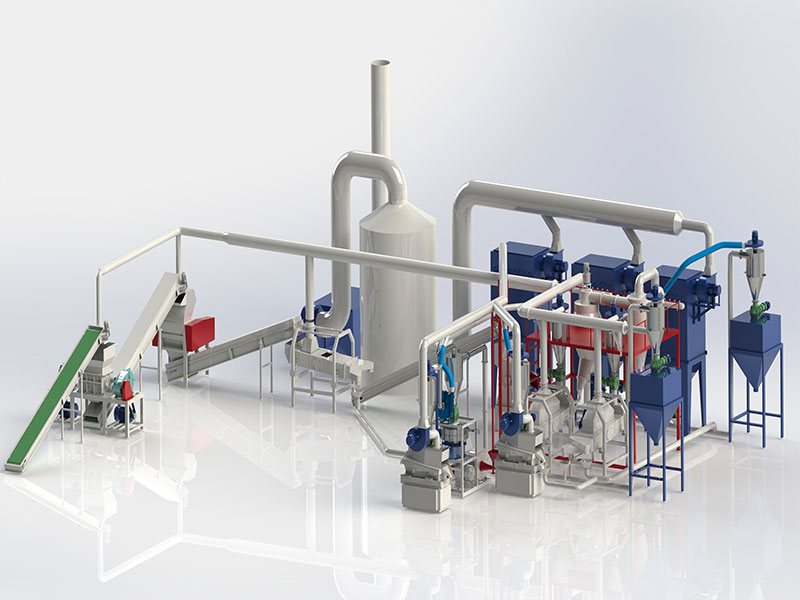

Implement Advanced Technologies and Automation

- Chemical Recovery Processes: Advanced chemical recovery units, costing $200,000 to $400,000, can efficiently extract valuable materials, enhancing both throughput and recovery rates.

Establish Strategic Partnerships and Collaboration

Collaborate with key industry stakeholders to reduce costs and access new opportunities:

- Battery Manufacturers: Partnerships provide a steady supply of used batteries and technical expertise.

- Energy Recycling Companies: Collaborations can explore second-life applications, creating additional revenue streams.

- Government Agencies: Engage with agencies to access incentives, grants, and regulatory support.

Focus on Research and Development

Continuous R&D efforts can lead to cost reductions and process optimizations:

- Process Optimization: Allocate around 5-10% of your budget to R&D for process improvements, aiming to streamline operations and reduce waste.

- Material Recovery Innovations: Explore innovative techniques for material recovery to maximize revenue.

- Sustainability Practices: Invest in sustainable practices to minimize environmental impact, which can also attract eco-conscious partners and customers.

Understanding the Cost of Recycling Electric Car Batteries

Understanding the cost of recycling electric car batteries involves evaluating factors such as initial investment, operational costs, and revenue streams. The scale of your operations significantly influences these costs, with small, medium, and large-scale facilities offering different advantages:

- Small-Scale Facilities: Lower initial investment but limited capacity and potential for revenue.

- Medium-Scale Facilities: Balanced approach with moderate investment and capacity, offering a good return on investment.

- Large-Scale Facilities: High initial investment but maximized efficiency and revenue potential due to economies of scale.

Curious about how spent lithium battery recycling lines work? Let’s explore YSX cutting-edge ewaste recycling solutions, request a demo, or learn how we customize recycling lines to fit your needs. Don’t miss out on reducing costs while boosting environmental impact!

Contact Us