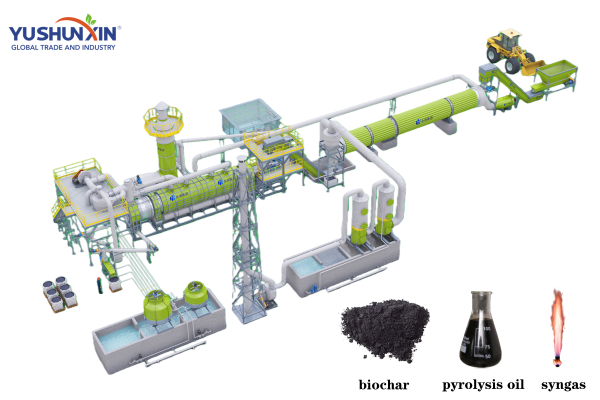

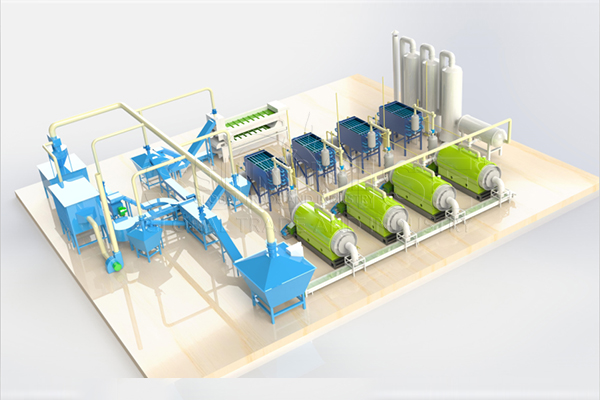

Technology changes fast, and electronic waste keeps piling up. Every efficient recycling plant needs reliable machines to handle different materials – whether it’s solar panel recycling, lithium battery recycling, waste tire recycling, solar panels recycling or circuit board recycling.

YSX shredding machines will help you to crush e-waste into reusable materials like glass, metal, and plastic, making recycling easier and more profitable. Do you know how YSX shredders can help your recycling business save money while protecting the environment?

Classification of shredders

Electronic waste shredders are specially designed to process used electronic equipment and appliances. These machines efficiently crush, separate, and recycle a variety of materials in e-waste, such as metal, plastic, and glass. Here are some common types of e-waste shredders.

Single Shaft Shredder

Features: Single-shaft design, usually with a rotating blade shaft, equipped with fixed blades.

Scope of application: Suitable for smaller-scale electronic waste treatment, such as hard disks, circuit boards, mobile phones, etc.

Advantages: Simple structure, easy maintenance, suitable for treating relatively homogeneous waste.

Double Shaft Shredder

Features: Double-shaft design, equipped with two sets of rotating blades, which can rotate in reverse.

Scope of application: Suitable for larger-scale electronic waste treatment, such as household appliances, computers, televisions, etc.

Advantages: Strong processing capacity, good crushing effect, suitable for treating many different types of waste.

Four Shaft Shredder

Features: Four-shaft design, usually with a more complex rotating blade structure, which can achieve more detailed crushing.

Scope of application: Suitable for high-demand electronic waste treatment, such as precision instruments, circuit boards, etc.

Advantages: Small crushing particle size, good sorting effect, suitable for treating high value-added waste.

Crusher-Shredder Combo

Features: Combines crushing and shredding functions in one, usually equipped with a multi-stage shredding system.

Scope of application: Suitable for electronic waste that requires multi-step processing, such as TVs, computers, etc.

Advantages: Integrated design, high processing efficiency, and small footprint.

Why You Need Shredder Machine in E-waste Recycling?

Top 5 Most Common Applications of Shredder Machines

The shredding machine is an essential part of waste tire recycling production line.

Most shredders can only handle hollow tires, but YSX shredder is different. Our double – shaft shredder has a powerful power system. Its high – power motor provides strong torque, easily tearing through solid tires. The knives are secret weapon. They’re patented, super hard, and wear – resistant. Tests show that our shredder can process solid tires several times faster than ordinary ones, with more uniform shredded pieces. If you need to shred waste solid tyres, YSX double – shaft shredder is the professional choice.

The shredder can also help you shred bullet shells.

YSX shredder is a powerful and versatile solution for processing electrical cables.

Whether it’s copper wires, which are highly valuable in the recycling industry due to their excellent electrical conductivity, or other types of wires such as aluminum – cored wires, communication cables, and automotive wiring harnesses, our shredder can handle them all with ease.

The customer sent us these heat sink fins to test shredder out. They want to see if our shredding way can break the fins just right for recycling.

If you also have products that you want to test on our machines, don’t hesitate to get in touch with us. We offer trial runs to ensure that our equipment meets your specific requirements before you make a purchase.

In additon, shredder can easily shred spent lithium-ion batteries!

Shredded lithium batteries have versatile applications. The crushed battery materials serve as a rich source for metal recovery, extracting critical elements like lithium, cobalt, nickel, and copper. These materials are vital for manufacturing new batteries, reducing reliance on raw mining and promoting circular economy practices. Additionally, processed lithium-battery granules can be integrated into construction materials, such as concrete additives, enhancing their durability and structural integrity. Therefore, shredders is important in sustainable lithium batteries recycling.

How Can We Help You When You Purchase Shredder Machine?

Contact Us