How do you disassemble old solar panel system in the PV panel recycling process? How much does solar disassembly equipment cost? Are there any proposals that can be used for reference? These problems we will solve for you in this article.

Top 3 machines in solar panel disassembly equipment

In the field of solar panel disassembly, several key machines play crucial roles. Here, we will introduce three kind: Solar Panel Deframing Machine, Photovoltaic Panel Glass Removal Machine and Dust Removal Equipment.

Solar Panel Deframing Machine

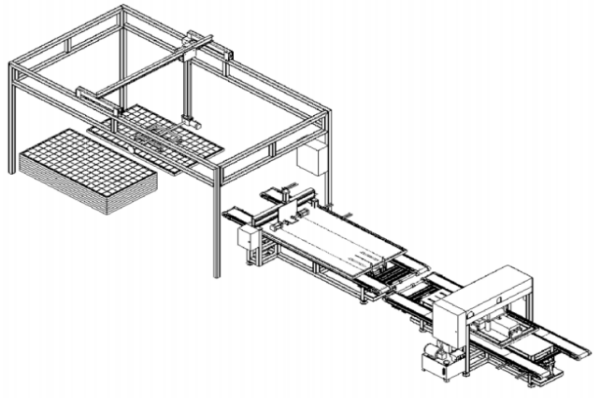

Solar panel deframing machine is responsible for removing the aluminum frames from scrap solar panels. It uses mechanical tools such as precision screwdrivers or cutting blades. The screwdrivers are programmed to precisely unscrew the screws fastening the frames, while the cutting blades can handle frames that are glued or clipped in place. This ensures a smooth and damage-free separation of the frames from the main body of the solar panel.

| Model | Rated Power | Weight | Size (m) | Capacity | Voltage | Certification | Price |

|---|---|---|---|---|---|---|---|

| YSX | 45kW | 6000kg | 30*7*4 | 200-1000kg/h | 220v/380v/customized | CE, ISO | 2,100$-7,200$ |

PV Panel Glass Removal Machine

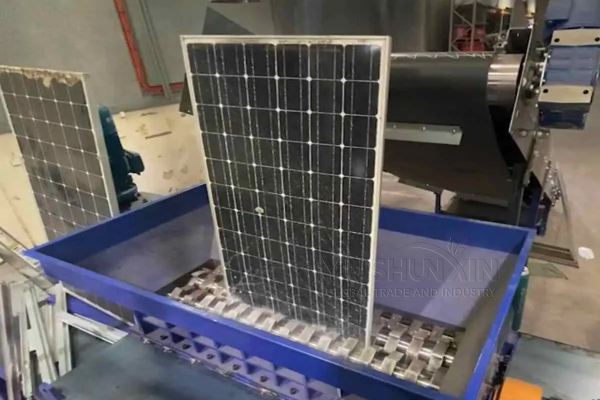

The function of solar panel cover glass removal machine is to separate the glass layer from the underlying solar cells. It first heats the panel to the appropriate temperature to make the adhesive material soft. Then, through mechanical separation devices like rollers or scrapers with controlled force, it carefully lifts the glass away from the cells.

Some customers worried about solar panel glass thickness. Don’t worry. It is applicable to various types of solar panels, including single glass solar panels and double glass modules. For double-glass panels, a two-step separation process might be required, but it can still effectively remove the glass layers.

| Model | Rated Power | Weight | Size (m) | Capacity | Voltage | Certification | Price |

|---|---|---|---|---|---|---|---|

| YSX | 55kW | 7500kg | 36*8*5 | 200-1000kg/h | 220v/380v/customized | CE, ISO | 2,800$-7,300$ |

Dust Removal Equipment

| Model | YSX |

|---|---|

| Airflow Rate | Adjustable from 1000 cubic meters per hour to 3000 cubic meters per hour |

| Filtration Efficiency | Over 99% with high-quality filters |

| Noise Level | Below 70 decibels |

| Voltage | 220v/380v/customized |

| Certification | CE, ISO |

| Price | 750$-2,140$ |

Function:

Dust Removal Equipment is essential in the solar panel dismantling process as it helps to remove dust and small debris generated during operations like deframing and glass removal. It creates a negative pressure environment through a powerful fan and sucks in the dusty air. The dust-laden air then passes through the filters where the dust is trapped, and the clean air is discharged back into the working area.

In conclusion, these three basic machines in scrap solar panel recycling equipment each have their own unique functions. Their combined use can ensure an efficient and environmentally friendly disassembly operation in the solar panel recycling industry.

As a professional manufacturer of scrapped solar panel recycling equipment, we have rich experience and perfect technical equipment, and has provided solar panel recycling solutions for many customers. If you need machines or want to know more about solar panel recycling business, please feel free to contact us for consultation.

How to design a solar panel dismantling proposal?

Proposal A: Recycling aluminum frames and junction boxes by PV panel disassembly machinery

If your goal for recycling solar panels is aluminum frames and junction boxes, you can refer to this process. Our meticulously designed solar panel disassembly equipment offers an efficient and reliable solution.

Get the junction boxes directly

The photovoltaic (PV) junction box is an important part of the solar panels. In most cases, the junction boxes can be removed without removing the entire frame. For example, the junction boxes of many solar panels are fixed to the main structure of the solar panel, rather than fixed to the frame, so the junction boxes can be directly used without removing the frame. However, if the aluminum frame sometimes blocks part of the junction box, then the frame removing machine will help.

remove the aluminum frame with solar panel deframing machine

Market Prices of Aluminum Frames and Junction Boxes of Solar Panels

In the international market, the recycling prices of solar panel components vary.

In the US, average-quality aluminum frames are around $0.44 – $0.66 per kilogram, with better ones up to $0.88 – $1.1 per kilogram, and junction boxes range from $0.5 – $3. In Germany, aluminum frames are about $0.55 – $0.77 per kilogram, and junction boxes from $0.88 – $2.75. Japan has stable aluminum frame prices of $0.6 – $0.8 per kilogram and junction box prices from $1 – $3. India’s aluminum frames are around $0.3 – $0.5 per kilogram, and junction boxes from $0.3 – $2.

These prices make the recycling business of aluminum frames and junction boxes lucrative. If you have interest, don’t hesitate to get in touch with us.

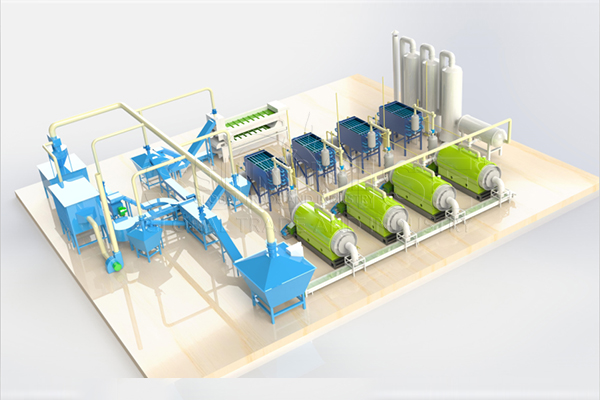

Proposal B: How can solar panel disassembly machinery help you recycle glass?

You can easily recycle aluminum frame and junction box in proposal A. However, looking at the remaining soft solar panels, maybe they are still worth recycling… Yes, what I mean is the glass on the panels. The glass content in a solar panel is around 70%. If you want to recycle the glass on them, you need to add a glass removal machine based on the proposal A.

Glass Removal Machine

Is recycled glass from solar panels valuable?

In international markets, the recycled glass from solar panels holds promising prospects.

In the US, prices can reach up to $100 – $150 per ton, especially when the glass quality meets high standards for reuse in construction or automotive industries.

In Europe, it fetches around €80 – €120 per ton, with a growing demand for sustainable building materials.

In Japan, prices range from ¥8,000 – ¥12,000 per ton, as the market values its contribution to energy-efficient and eco-friendly applications.

Such lucrative prices make recycling solar panel glass a worthy investment.

How to further recycle disassembled PV panels?

Maybe you want more kinds of final products than mentioned above, right? More delicate final products can bring you higher selling prices and profits. Here comes the question: Can solar panel disassembly equipment help you recycle silicon, copper, and aluminum powder? Obviously you need to add a few more machines to achieve the effect you want. So now we’ll provide you with solutions for recycling silicon, copper powder, and aluminum powder in solar panels.

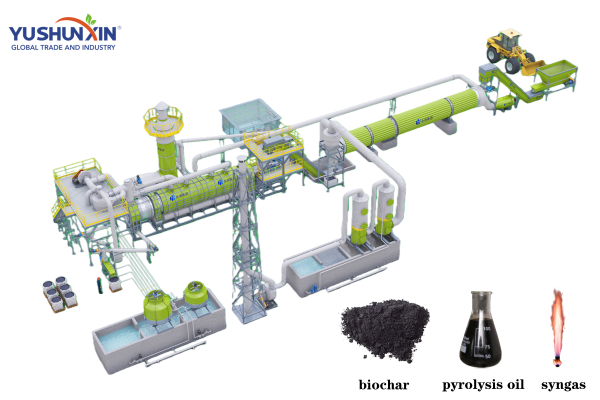

Physical shredding solar panels

Silicon wafers are the core components of solar panels, you can use physical shredding machine to recycle silicon. After removing the glass and junction box, the remaining parts of the panel can be broken into small pieces by e-waste shredder. The shredder we designed has adjustable strength, and the stainless steel material is not easy to rust. After shredding, the silicon wafers are then separated from other materials (such as backplane materials, copper foil, etc.) using magnetic separators based on physical properties such as density differences or electromagnetic properties.

Sorting and screening valuable materials

Since the shredded materials differ in composition and properties, they need to be sorted using sorting and screening equipment. For example, gravity sorting equipment and vibration screening equipment are used to separate copper powder and aluminum powder based on weight, material and other characteristics for subsequent recycling.

(As mentioned above, these machines can make your final product more refined. But in this article we focus on discussing solar panel disassembly equipment, so you can only see a brief overview here. If you have interest in all the equipment in the whole process of solar panel recycling, you can click on this article about solar panel recycling machine to know more.)

How profitable is the solar panel recycling business?

If you want to know the cost of an entire solar panel recycling production line, contact us. Whether you’re interested in recycling solar cells, glass, aluminum frames, or obtaining purer silicon powder or metal powder, we offer tailored solutions.

Contact Us