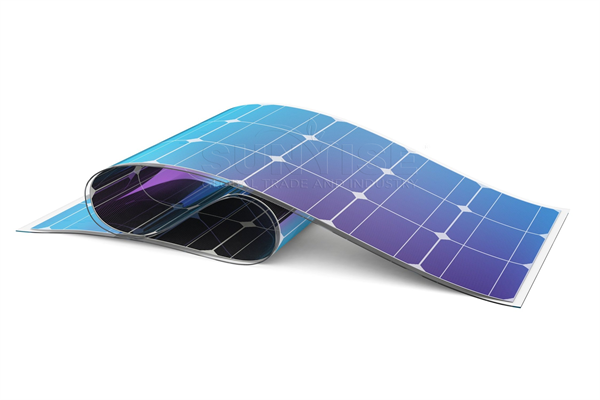

The principal components of a photovoltaic (PV) solar panel consist of high-quality glass, aluminum frames, polymers, silicon, copper, and silver paste. By our solar panels recycling machine (solutions), you can successfully recycle each of these materials, with recovery rates reaching up to 95%.

What kind of solar panels are recyclable?

If you don’t find your e-waste item(s) listed above, please get in touch with us. YSX will help you.

PV Panel Frame Dismantling Machine

The solar photovoltaic panel deframing machine is suitable for the dismantling and recycling of scrap solar panel aluminum frames of various sizes and types. Firstly, it can precisely target and start the process of separating the aluminum frame. Subsequently, during this operation, it manages to finally remove 80%-95% of the glass.

Solar Panels Glass Removing Machine

Removing most of the glass from the surface. Processing Width 1250mm.

Solar Panels Two-shaft Shredder

Shredder can initially process large quantities of solar panels. Firstly, it quickly breaks them into small pieces, thereby improving the efficiency of the entire recycling processing line. Subsequently, the smaller material size makes the subsequent equipment (such as sorters, crushers, etc.) work more efficiently.

Crusher (Hammer Mill) for Photovoltaic Panels

After shredding, the fragmented materials are passed through a crusher. This machine is designed to further break down materials like glass, silicon wafers, and other components into even smaller particles. Crushing is a critical step in the recycling process as it prepares the materials for separation techniques that will isolate valuable metals and silicon.

What Solar Panel Recycling Machine Sorts Those Materials?

Magnetic Separator

Used to separate iron and other magnetic metals from mixed materials. Magnetic separator uses the attraction of a magnetic field to separate magnetic metals from non-magnetic materials, thereby improving the purity of the material.

Cyclone separator

Cyclone separator is a highly efficient device that employs centrifugal force to effectively separate lighter materials from heavier ones within a mixture. As the mixture is introduced into the cyclone separator, it undergoes rapid spinning, which generates a powerful vortex inside the chamber. This vortex action causes the heavier particles to be flung outward towards the outer edges of the separator. Subsequently, the lighter materials are allowed to stay near the center. As a result, a clear and efficient separation process is facilitated.

High-voltage electrostatic separator

The remaining copper and EVA glue that are not completely separated enter the high-voltage electrostatic separator, which separates the copper based on conductivity.

Gravity Separator

Gravity separator is the innovative device that effectively separates copper and EVA glue based on the varying densities of their particles. By utilizing the principle of gravity, this separator distinguishes materials with different densities. Firstly, it carefully separates the various components of waste solar panels. Through this process, impurities are significantly reduced. Secondly, this enhancement in purity leads to a notable improvement in both the efficiency and precision of the recycling process. As a result, the reuse rate of waste solar panels is substantially increased. Consequently, it contributes to more sustainable and eco – friendly practices in the management and recycling of solar panel materials.

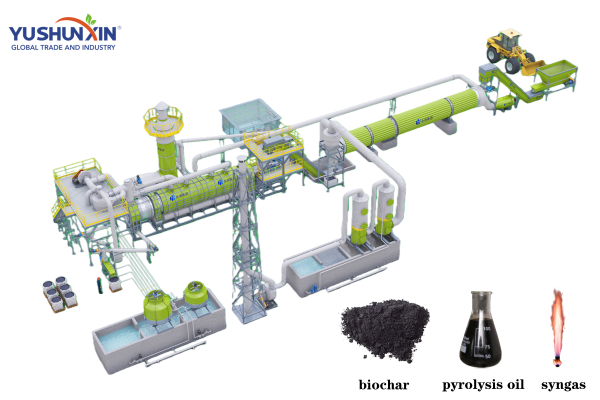

Which Solar Panel Recycling Machine is in the Heat Treatment Process?

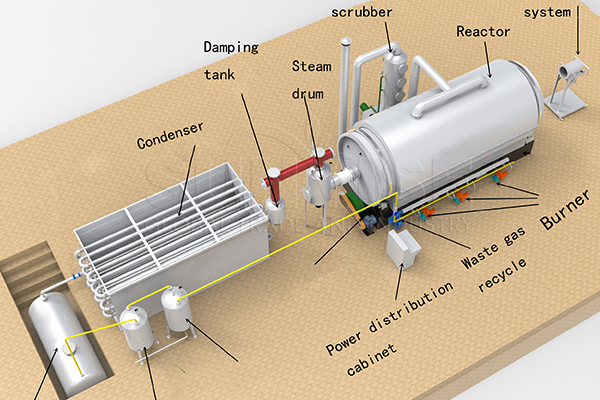

The pyrolysis furnace creates a high – temp, oxygen – free space. Solar panels are heated to 600°C, causing materials to decompose. Some turn to gas, leaving slag with heavy metals needing extra treatment. The condensing tube converts gas to liquid. The gas separation package purifies gas – liquid mixtures. The spray tower cleans exhaust gases, reducing pollution and meeting standards.

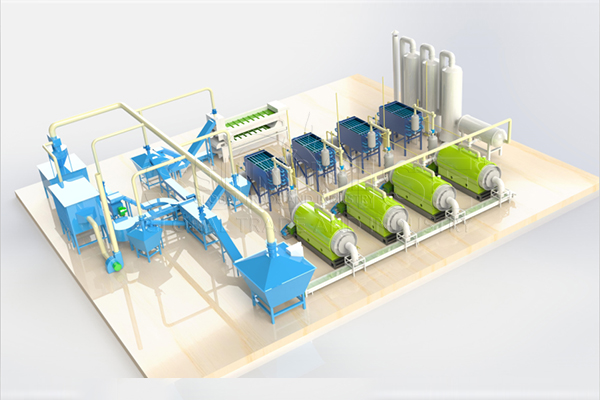

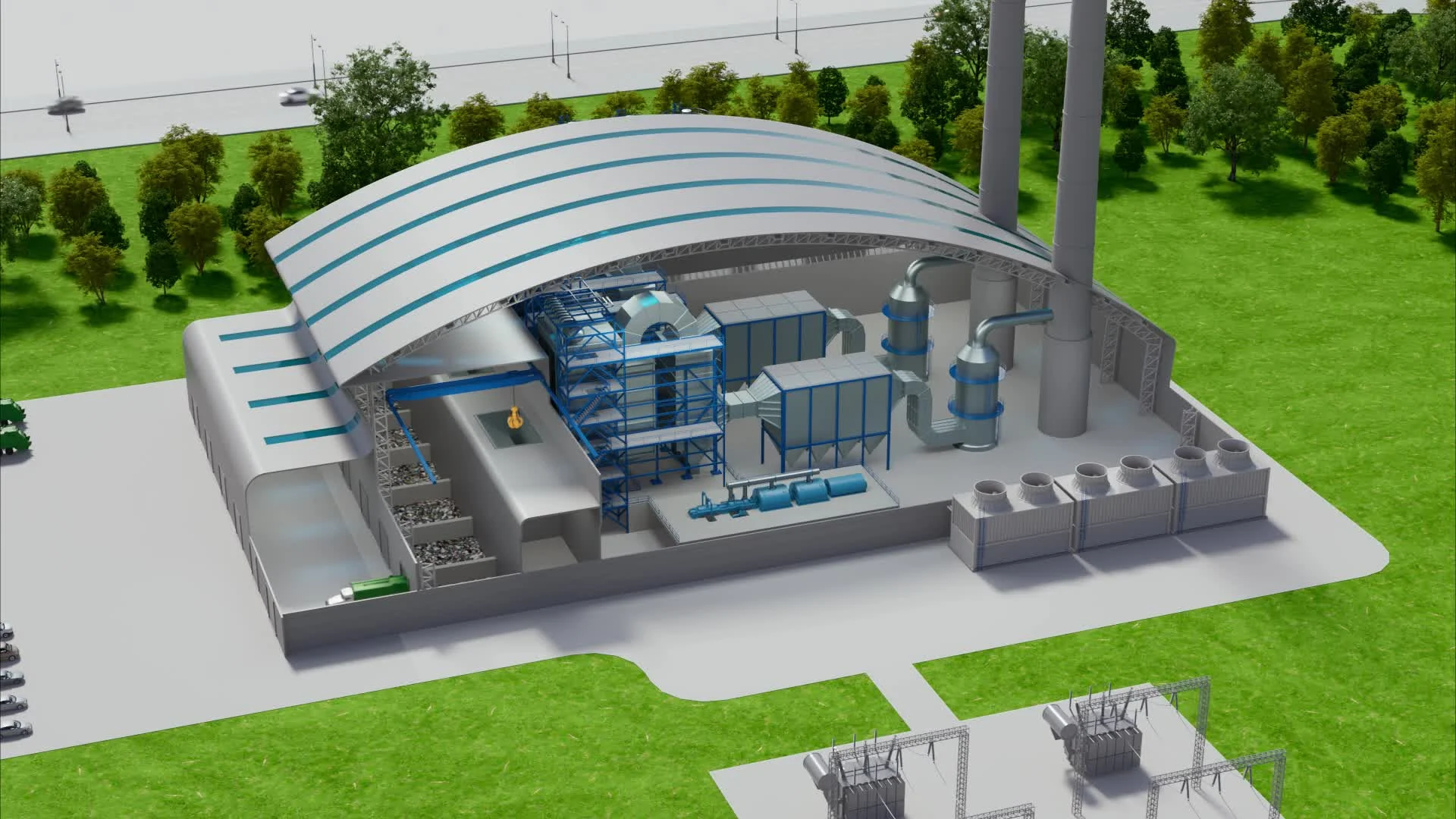

How to Design Solar Panel Recycling Factory?

What do People Recycle Solar Panels for?

Why Choose YUSHUNXIN as Your Supplier of Solar Panel Recycling Machines?

The Advantages of YSX Solar Panel Recycling Machines

Solar panel recycling equipment parameters for your reference

| Model | YSX-300 | YSX-500 | YSX-1000 |

| Capacity | 300 Kg/H | 500 Kg/H | 1000 Kg/H |

| Power | 102 Kw | 134 Kw | 194 Kw |

| Weight | 15 Ton | 20 Ton | 30 Ton |

| Dimension (m) | 20*5*5 | 25*6*5 | 30*6*5 |

What is the General Price of Solar Panel Recycling Line?

Approximately $50,000 – $70,000. Small-scale lines are suitable for small to medium enterprises or startups, relatively simple and low-cost.

Approximately $80,000 – $150,000. In addition to the equipment in small-scale lines, medium-scale lines require higher-specification equipment. Medium-scale lines require more efficient equipment and automation systems to handle medium-scale processing needs.

Approximately $160,000 – $200,000 or more. Large-scale lines need the most advanced equipment and systems to maximize recycling efficiency and environmental compliance.

Contact Us