As a leading recycling solutions provider, SUNRISE is committed to helping you set up a solar panel recycling plant. Solar energy is becoming increasingly popular as a renewable energy source, but with this growth comes an inevitable challenge: recycling outdated and damaged solar panels. In this article, we’ll let you know the cost of setting up a solar panel recycling plant, as well as various options based on different production capacities.

Initial Setup Costs of Solar Panel Recycling Plant

When setting up a solar panel recycling plant, one of the first and most significant considerations is the initial investment. This involves several key components.

Operational and Maintenance Costs of Solar Panel Recycling Plant

Once the plant is up and running, ongoing operational and maintenance costs will be your primary financial concern. These costs include:

The price difference between physical and chemical methods of PV panel recycling

In the recycling of photovoltaic panels, both physical and chemical methods are available, but they differ significantly in cost.

Physical recycling methods

Physical recycling methods have shown distinct advantages in terms of cost-effectiveness. For instance, the initial investment for a set of physical recycling equipment, such as a shredder (around $20,000 – $30,000), a vibrating screen ($3,000 – $8,000), a magnetic separator ($4,000 – $10,000), and a centrifugal separator ($6,000 – $12,000), totals approximately $33,000 – $60,000. The operational costs are relatively low as well. The power consumption of these physical devices is within a reasonable range. For example, the shredder operates at 50kW – 100kW, the vibrating screen at 3kW – 8kW, the magnetic separator at 4kW – 10kW, and the centrifugal separator at 6kW – 12kW. Considering an average electricity price, the power cost is manageable.

Batch type pyrolysis machine for solar panels recycling

Chemical recycling methods

On the contrary, chemical recycling methods involve more complex and expensive processes. The equipment required for chemical recycling, like a pyrolysis furnace which costs around $15,000 – $50,000, a condenser ($4,000 – $12,000), and a gas purification unit ($6,000 – $18,000), already amounts to a significant sum. Moreover, the chemical reagents used in the process add to the cost. The overall cost for setting up a chemical recycling line can be as high as $25,000 – $80,000 or even more, depending on the scale and complexity. Additionally, the chemical recycling process demands strict environmental protection measures, which further increase the operational and maintenance costs.

In conclusion, physical recycling methods for photovoltaic panels offer a more economical and practical solution compared to chemical methods, not only in terms of the initial investment but also in the long-term operation and maintenance costs. This makes physical recycling a more favorable choice for the sustainable management of photovoltaic panel waste.

Production Capacity and Cost Differences of Solar Panel Recycling Plant

The cost of establishing a solar panel recycling plant varies significantly based on the desired production capacity. Here’s a breakdown of costs for different production scales.

Three Kinds of Solar Panel Recycling Lines Based on Budget

Price Difference Between Solar Panel Disassembly and Crushing-Screening Lines

When it comes to solar panel recycling plants, there are differences in the price of disassembly lines and crushing and screening lines.

If you only aim to obtain the frames of solar panels as the final product, a disassembly line might be more suitable. The cost of a basic disassembly line could range from $80,000 to $150,000, which mainly focuses on separating the frames from the panels.

However, if you target silicon powder, copper powder, and aluminum powder as end products, a crushing and screening line is essential. Such a line usually has a higher price, starting from around $150,000 and potentially exceeding $300,000. It involves more complex processes and equipment for crushing the panels and then screening out the different powders precisely.

How to Make Your Solar Panel Recycling Line Profitable?

Selecting top-notch recycling machine is the cornerstone of profitability. Advanced solar panel recycling machine minimizes waste and reduces your production time, increasing overall productivity. By investing in the right solar panel recycling machinery, your solar panel processing line can extract valuable products of superior quality, maximizing revenue and ensuring a profitable venture in the long run.

High-quality deframing machines, glass removing machine, shredders, crushers, and sorting equipment ensure efficient and precise processing. This leads to a higher purity of recovered materials such as silicon, copper, and aluminum. With better quality outputs, you can command premium prices in the market. For instance, pure silicon can be sold at a higher rate to the semiconductor industry, and refined copper has greater value in the electronics sector.

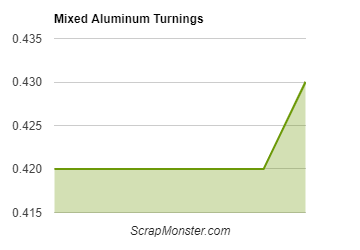

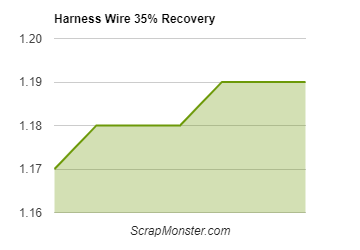

Additionally, now the price of the finished materials after crushing photovoltaic module scrap is very considerable. The following is the copper and aluminum scrap cost for reference.

Why Should You Choose Us?

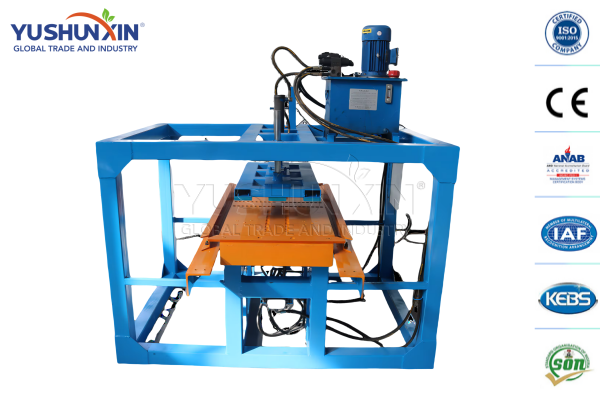

Here are our machines’ technical advantages that you must know:

Compared with other photovoltaic panel recycling equipment on the market, our equipment has an absolute advantage in recycling purity. After verification by a third-party testing agency, the purity of silicon materials recycled by our equipment can reach more than 99.9%, which is much higher than the industry average. It can be directly used in the production of high-end photovoltaic products, increasing the added value of recycled materials.

Energy-saving characteristics of the equipment. Our photovoltaic panel recycling equipment uses a new energy-saving motor, which can reduce energy consumption by more than 30% compared to traditional equipment. We aim to help customers save a lot of costs in long-term operations.

Customizable Solutions for Your Solar Panel Recycling Plant: Partner with YUSHUNXIN for Success!

The following is several YUSHUNXIN recycling production line schemes for your reference.

Basic Recycling Line: Aluminum Frame and Glass Particle Recovery

The first scheme is suitable for those who only aim to recycle aluminum frames and glass particles. It involves disassembling the frame and crushing the glass, and the process ends there. The equipment required includes a frame disassembly machine, a glass crusher, and basic safety equipment. The cost for this scheme ranges from $10,000 to $30,000.

Comprehensive PV Panel Recycling Solution for Multiple Materials

If you aim to recycle aluminum powder, copper powder, and silicon, this scheme is a good choice for you. It represents a complete PV panel recycling process, which includes frame disassembly, glass removal, crushing, screening, and dust removal equipment. The production line would consist of a frame disassembly unit, glass removal equipment, a powerful two-shaft shredding machine, a variety of screening devices (such as vibration screens and air classifiers), magnetic separators, electrostatic separators, and advanced dust collectors. The total cost for this comprehensive scheme is in the range of $50,000 to $150,000.

Backsheet-focused Crushing and Screening Recycling Option

The third scheme includes only crushing, screening machine, and dust removal equipment. It targets customers whose raw materials are PV panel backsheets after frame disassembly and junction box removal. The price for this scheme is approximately $30,000 to $80,000.

Each project is unique. Feel free to contact us, we will customize the solution for you according to your needs.

Contact Us