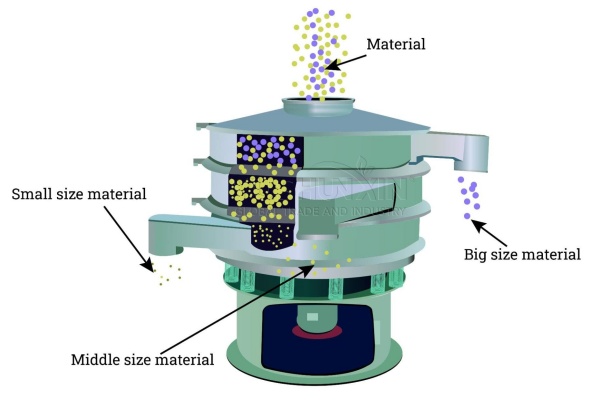

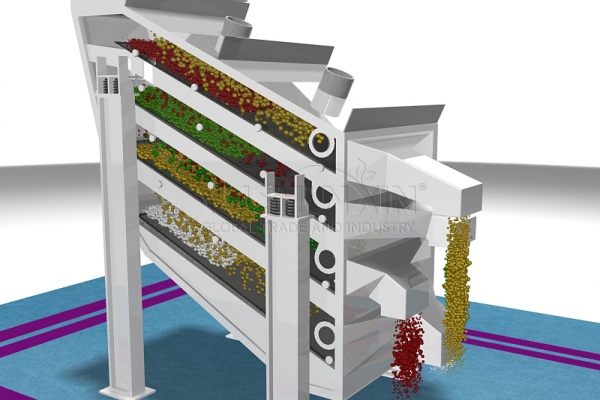

To optimally separate e-waste by sort and size is a challenge. Part of the installation for sorting and screening waste is vibrating screen separator. Now let’s discuss the types of vibrating screen separator, what kind of materials are the screening equipment suitable for, and the screening accuracy of the vibration screening machine.

As the vibrating screen manufacturer, we have many years of experience in designing and building vibrating screening machinery for many e-waste recycling industries. For more information please contact our sales team.

Briefly, vibrating screen separators offer flexible solutions for handling a wide range of materials in e-waste recycling. If you require further information about our screening equipment, please do not hesitate to contact us. Our team of experts is available to provide detailed guidance and support, assisting you in making the most suitable choices for your e-waste recycling operations.

In a nutshell, the screening accuracy of a vibration screening machine is a complex interplay of multiple elements. The mesh size, vibrating frequency, and raw material characteristics all contribute to the overall effectiveness of the screening process. Our commitment is to continuously optimize our machine to meet the diverse demands of the e-waste recycling industry. Whether you are looking for a particular variation or would like to know more about the number of screening elements, screening decks or the screen mesh, please feel free to contact us.

In addition, if you have interest in lithium battery recycling plant, solar panel recycling machine, circuit board recycling lines, waste tire pyrolysis recycling line and other electronic waste recycling projects, please contact us. Electronic waste recycling machines and solutions, we are professional!

Contact Us