In the ever-evolving field of electronics and electrical engineering, the demand for efficient and advanced automatic Wire Stripping Machines is set to reach new heights by 2025. These machines will be the cornerstone of wire processing operations, ensuring precision, speed, and reliability.

Cutting-Edge Technology

The top automatic Wire Stripping Machines of 2025 will boast cutting-edge technology. They will feature highly intelligent control systems, powered by artificial intelligence and machine learning algorithms. These systems will be capable of instantaneously analyzing the type, gauge, and material of the wire being fed into the machine.

Based on this analysis, the machine will automatically adjust its stripping parameters, such as blade pressure, cutting depth, and stripping speed, to achieve the most optimal and accurate stripping results. This eliminates the need for time-consuming manual adjustments and significantly reduces the risk of wire damage or improper stripping.

High Speed and Productivity

Speed and productivity will be another hallmark of these machines. With advanced motor and drive technologies, they will be able to process wires at an unprecedented rate. High-speed spindles and precision feed mechanisms will work in harmony to handle large volumes of wires in a short span of time.

Accuracy and Consistency

Accuracy and consistency are non-negotiable in wire stripping. The 2025 models will incorporate ultra-precise blade assemblies and positioning systems. Laser-guided alignment and feedback loops will ensure that the stripping process occurs with micron-level precision.

Versatility

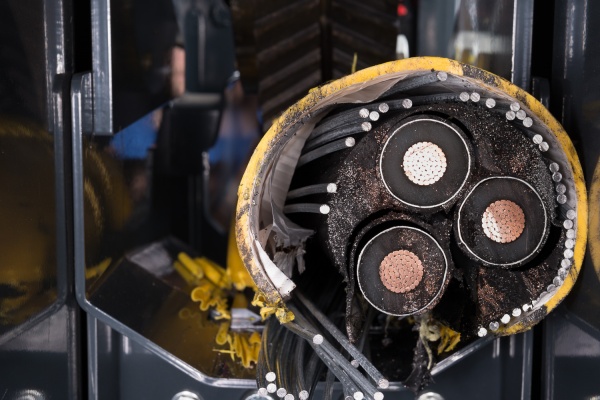

Moreover, these machines will be designed with versatility in mind. They will be able to handle a wide variety of wire types, from thin and delicate wires used in electronics to thick and heavy-duty cables used in power transmission. Adjustable clamping mechanisms and interchangeable blade sets will allow for seamless transitions between different wire gauges and materials. This flexibility will make them indispensable in a diverse range of industries, including consumer electronics, renewable energy, and industrial automation.

Safety Features

The Automatic Wire Stripping Machines of 2025 will also place a strong emphasis on safety. They will be equipped with comprehensive safety features, such as emergency stop buttons, safety interlocks, and protective enclosures. These features will prevent accidental contact with moving parts and protect operators from potential injuries. Additionally, the machines will comply with the strictest safety standards and regulations, providing peace of mind to both manufacturers and users.

The top Automatic Wire Stripping Machines of 2025 will revolutionize the way wires are processed. With their advanced technology, high speed, accuracy, versatility, user-friendly interfaces, and safety features, they will be the go-to choice for industries that rely on precise and efficient wire stripping. These machines will not only enhance productivity and quality but also drive innovation and growth in the electrical and electronics sectors.

Contact Us