In Ghana, the current methods of tire recycling are far from ideal. Many informal recycling operations pose significant risks to both the environment and the health of the people involved. These rudimentary methods often involve burning tires in the open, which releases harmful pollutants and toxins into the air, soil, and water. Workers are exposed to hazardous fumes and substances, leading to various respiratory and other health problems. It is crucial to adopt a more sustainable and efficient approach to tire recycling.

The first step in recycling tires in Ghana is to shred the tires by a shredder

Shredding is an essential step in recycling tires in Ghana. Many recyclers in Ghana choose to cut waste tires manually, but it is not worth it to cut tires only by manpower. It seems that it can save equipment costs, but the actual inefficiency will lead to smaller profits.

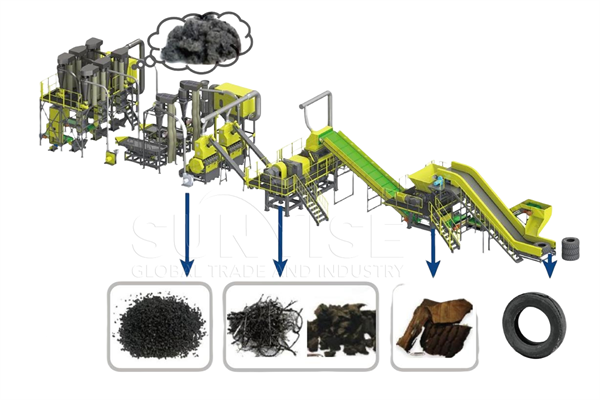

The equipment used here is crucial for the success of the recycling process. This requires specialized double-shaft shredding machines. The tires are fed into the primary shredder, which uses powerful rotating blades to cut the tires into smaller pieces. These initial shreds are then passed through a secondary shredder for further reduction in size. The shredded tire pieces can be used in various applications such as in the production of rubberized asphalt or as a component in playground surfaces. Crushed tires are very easy to sell. Later in this article, we will talk about a customer who specializes in selling rubber fragments for profit.

In addition, for shredding, there are different types of shredders available, ranging from single-shaft to multi-shaft designs, each with its own advantages in terms of throughput and shredding quality. However, we usually recommend the double-shaft shredding machine to our customers, one of the reasons being its incredible power.

Then use a pyrolysis furnace after shredding

After shredding, the next stage is pyrolysis. The pyrolysis furnaces come in various sizes and configurations, such as batch reactors and continuous reactors. The shredded tires are loaded into a pyrolysis reactor. The reactor is heated to a specific temperature range, typically between 400 to 600 degrees Celsius in a controlled environment. This process breaks down the rubber polymers in the tires through thermal decomposition.

As a result, valuable products are obtained. The pyrolysis process yields pyrolysis oil, which can be used as a fuel or a feedstock in the chemical industry. It also produces carbon black, which has applications in the rubber and plastics industries, and combustible gases that can be used to provide heat for the pyrolysis process itself, making it more energy-efficient. Whether pyrolysis oil or carbon black, you can sell it locally in Ghana.

Is there any other equipment help you properly recycle tires?

Actually the answer depends on you. If you want to build an automatic tire recycling production line, then the answer is yes, you need some auxiliary equipment. There is a need for supporting equipment like conveyors to transport the tires and shredded materials between different processing stages, condensers to cool and collect the pyrolysis oil, and gas purification systems to treat the combustible gases, etc. You don’t need to worry about these auxiliary equipment. Our Tech Dept. will design the proposal for you, including how many and how long the conveyor belts you need, etc.

However, if your budget is small, some auxiliary equipment can be removed. Please contact us and we will design the best solution for you.

The case for recycling tires the right way in Ghana

Half a year ago, a Ghanaian customer approached us with inquiries about setting up a tire recycling plant. His specific requirement was to recycle only the shredded rubber and did not have the need for oil refining. Based on his needs, we customized a small-scale tire shredding line suitable for the Ghanaian market. This line was designed to efficiently process a specific volume of tires per day, providing him with high-quality shredded rubber for further use. The customer was satisfied with the solution as it met his production requirements and budget.

If you are also have interest in the tire recycling business in Ghana or have any questions regarding the right recycling methods and machine, do not hesitate to e-mail us. We have the expertise and experience to provide you with tailored solutions to meet your unique needs and help you establish a sustainable tire recycling operation.

Contact Us